An international research team has assessed the impact of soldering flux on heterojunction solar cells and has discovered that the composition of this component is the key to prevent large cracks and significant peeling.

Researchers from the University of New South Wales (UNSW) and the Chinese Canadian PV modulemaker Canadian solar zon-Zon have investigated the effect of soldering flux on both top-cone and heterojunction (HJT) solar cells and have established that the choice of this component is the key to avoid possible module errors.

“Our study immediately deals with a critical issue: the sensitivity of HJT sun cells to soldering flux-induced demolition, in particular in metallization and the ITO layer,” said the main author of the research, Bram Hoex, said PV -Magazine. “We have established that existing pores in silver metallization make flux penetration possible, which activates chemical reactions that break down contact integrity.”

Hoex also explained that by conducting experiments at cell level instead of testing at module level, the research team could accelerate the failure analysis process with a maximum of two orders of size, making rapid identification of degradation mechanisms possible. “This approach offers faster insights into material compatibility and reliability, which greatly improves the efficiency of research and industrial evaluation of soldering blocks for HJT cells,” he added.

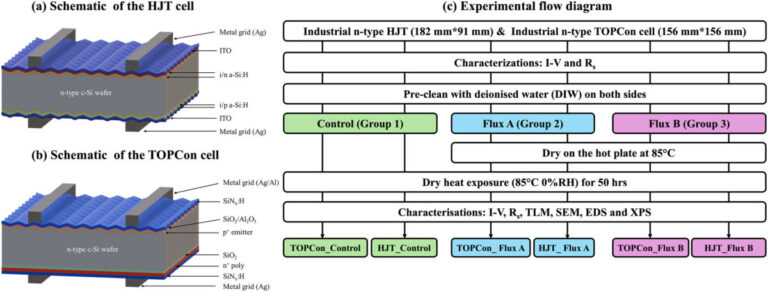

The scientists analyzed the effect of soldering flux on half-cut bifacial N-type Silicium HJT cells of 182 mm x 91 mm and bifacial N-type top-con sun cells with a size of 156 mm x 156 mm, where both cell types are from commercial production lines and are processed with two types of commercial solder clux called Flux A and Flux B.

“Flux A is a halid -free soldering flux, which means that it contains none of halogen -derived ions, while Flux B is a halogen -free soldering flower that excludes elements of the halogen group,” the scientists explained. “Both fluxes were heated to 120 ° C to guarantee the complete evaporation of the alcohol.”

They divided the analyzed cells into three groups: a control group with two topcon cells and two HJT cells that were not exposed to a solder clux; the Flux A group with two topcon cells and two HJT cells that were treated with Flux A on both surfaces; And the Flux B group consisting of two topcon cells and two HJT cells that were treated with Flux B on both surfaces.

The analysis showed that the topcon cells remained stable under dry heat tests at 85 ° C without breakdown, while the HJT cells showed serious breakdown, with power losses of approximately 61% riot with flux A and approximately 55% riot after 50 hours .

The power losses in the HJT cells were found to be caused by holes in the metallization layer, which facilitates the penetration of soldering, which leads to chemical reactions that break down the performance. Furthermore, it was established that the IndiumTin oxide (ITO) layer in HJT cells is very sensitive to damage caused by solder clux.

“The primary director of this demolition was an increase in contact resistance on both the front and back surfaces, which resulted in a pronounced rise in resistance,” the academics emphasized. “This increased series resistance stemes from considerable damage/corrosion to the ITO layers and metal contacts, in particular in the form of peeling in some ITO areas and cracking in the metal electrodes. Existing pores or holes in the metal electrode probably let the soldering flower penetrate and react chemically with AG particles and bindresin, which is worse for cracking after exposure to dry heat. “

The research team concluded that HJT sun cells are vulnerable to the demolition of soldering, even in encapsulated modules with low water vapor transmission materials. “Careful selection of soldering flux is crucial to prevent long-term performance losses in HJT modules,” said Hoex. “Suppliergatasheets may miss critical information about flux composition and potential impact. Independent component analysis is highly recommended before large -scale production. “

The analysis was described in “The influence of soldering flux on the stability of heterojunction and topcon sun cells“Which was recently published in Progress in photovoltaic.

This work builds on a part of the earlier work of UNSW, including a study that the Vulnerability of topcon sun cells for contact corrosion, research that identifies three top-cone panel error types that are absent in perc products, and a work that rates the impact of the breakdown in heterojunction solar cells under accelerated moist heating tests, among other things.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.