IEA-PVPS has conceived a new test method and analysis of the impact of curvature in vehicle-integrated photovoltaic surfaces (VIPV) surfaces. In the course of an 8-day summer study in Southeast France, the researchers discovered that the curvature caused non-uniformity to 261W/m² and 13 ° C respectively due to irradiation and temperature.

A recent report from the Photovoltaic Power Systems Program (IEA-PVPPS) of the International Energy Agency has presented a new test setup for curved vehicle-integrated PV (VIPV) surfaces.

The research work includes the results of an 8-day study in August 2023 in Le Bourget du Lac, France, which shows that VIPV surface curves of non-uniformity of a maximum of 261W/M2 and 13 ° C respectively can cause.

The researchers said that compared to a flat PV surface, the VIPV with a curvature beam equal to 3 m experienced an energy loss of 17% on a sunny day and 6% on rainy days.

Separate cell measurements were performed every minute in the experiments. In addition, the research team analyzed how curved PV roofs influence the performance, uniformity of solar radiation and temperature.

The researchers recommend optimizing energy production, VIPV product teams can increase the number of maximum Power Point Tracking (MPPT) channels and think about it to flatter the PV surface to optimize the energy collection naturally.

However, each of the optimization proposals has a challenge. “A very flat roof is against the trend in the car industry,” said co-author Bertrand Chambion of the French alternative energies and Atomic Energy Commission (CEA) told PV -Magazine. “And more MPPT channels increase the panel costs and system complexity.”

The hope of publishing the report, according to Chambion, is to increase the consciousness of the manufacturers of original equipment (OEM), vehicle manufacturers, stakeholders and PV industrial researchers about the factors that influence the VIPV performance and potential solutions.

Experimental attitude

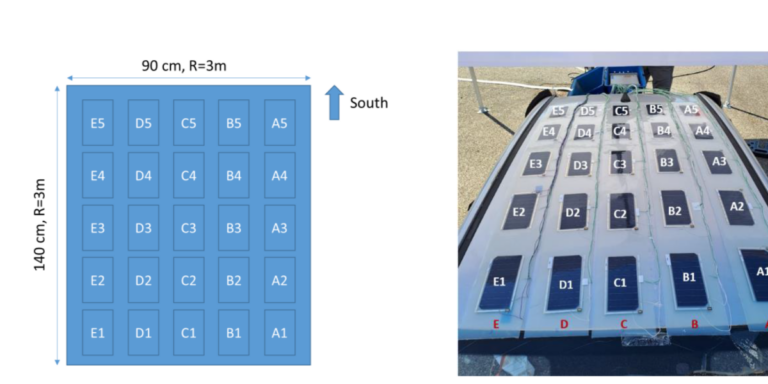

The Outdoor PV monitoring test bank described in the Task 17 report is specifically designed for curved suns of a passenger vehicle. The team used it for monitoring solar radiation and temperature, the collection of data to measure the impact and non-uniformity in light incidence angle over the VIPV module surface.

The team chose to design a matrix of individual solar cells instead of using commercial photo dances for the test setup. “It is less complex, easy to integrate and much more representative of the final application. The resulting measurements can be used to validate the model, “said Chambion.

The setup contained a 5 × 5 matrix of M6 format, 9-bus bar Perc solar cells, thermocouples, irradiation and temperature sensors. In addition, a multi-channel data logger, plywood, a mockup of a VIPV roof and a special energy management system (EMS) is to check radiation and temperature data per minute.

Individual cell measurements were performed every minute. The test panel experienced three weather scenarios: rainy, sunny and cloudy, in a location without shade. It had a southern exposure and the installation was representative of vehicle random azimut orientation during the parking phase.

The report, “Radiation and temperature uniformity on a feed roof“Is free to download.

Looking ahead, the researchers have recommended a one -year project to collect representative data, and noticed that other locations should also be tested.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.