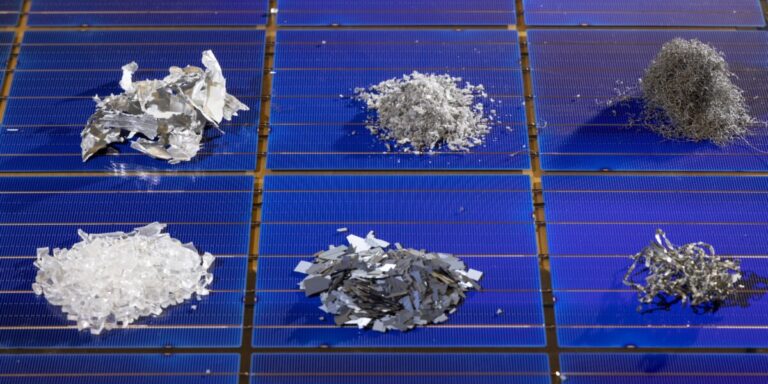

An international team of industry and researchers develops technology and methods to improve industry’s ability to recycle dismantled solar panels, avoid waste and focus on recovery of silicon, silver, glass and polymers with a purity that is sufficient for further Use in the PV industry or afterwards.

A European Consortium, coordinated by the Norway -based research agency Sintef, is intended to reach a recycling speed of 70 to 90% for important materials for the end of life (EOL), including silicon, metals, glass and polymer recovery at high purity levels. The multi -year Horizon Europe Research Project, called Quasar, has received € 7.1 million in financing.

“Nowadays mechanical recycling processes dominate the current market, and these processes have been optimized for compliance with laws based on recycled weight rather than value and economy,” said Martin Bellmann, senior business developer and quasar project coordinator, said PV Magazine. “The success and profitability of recycling largely depends on the ability to minimize the contamination between different materials, to insulate hazardous substances and to restore high purity fractions of valuable and energy-intensive materials.”

The group says it uses a holistic or end-to-end circular approach to start the limited recycling and recovery of today, which is usually aimed at aluminum frames and glass.

One of the challenges to overcome is how to deal with encapsulation polymers. Another challenge is the evolving design of new generations of solar panels, which differ in size, properties and material composition, making it difficult to create a one-size-fits-all solution, according to Bellmann.

The project was launched in September 2023 with a duration of four years and has already produced a detailed report that quantifies important materials and identifies EOL sources in the European Union for sustainable waste management. It also launched a Best Practice Guide for Veld Inspectorate of Solar Panel to promote sustainable solar panel handling from inspection to recycling.

The team will build two pilot lines, one with delamination of chemical treatment and the other on the basis of water jet telamination, while the total process is expected to be improved by applying digital technologies and processes. For example, digital product passports that make it possible to follow and management of solar panels equipped with sensor about their life cycle, information about production, material composition and records.

Technology is also being developed to enable rapid, non-destructive test methods to assess the state of EOL panels in the field and with waste treatment facilities to decide whether they are reused, repaired or recycled.

The quasar approach is said to take into account the Supply Chain, including concepts of reverse logistics technologies, machine learning, product life cycle information management (Plim) based on digital twin user and best practices for sorting, as well as warehouse operations, testing, repair and reuse.

The research consortium includes manufacturers of PV modules, PV system operators on tools, collectors, recyclers and end users of recycled secondary raw materials. In random order, the participants are Sintef, Elkem, Equinor Energy, Buhck Re.Energy (2ndlife Solar), Luxchemtech, Solitek, Scatec, Rosi, Soren, Dow Silicones Belgium, Dow Chemical Iberica, Institut Photovoltaïen France (IPvf) , Hochschule Offenburg, Electric Power Research Institute Inc (EPRI), Renewables Norway and Norner Research.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.