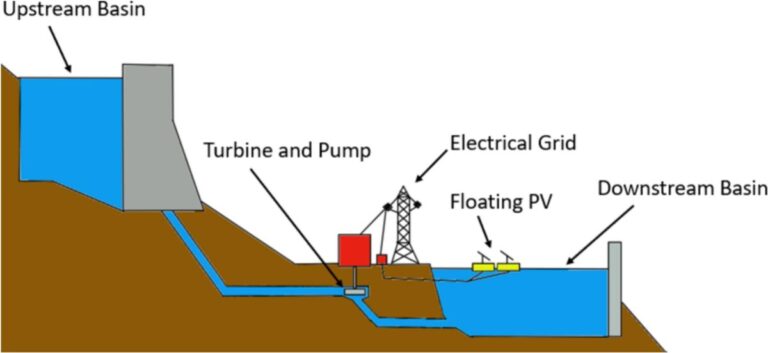

Researchers in Italy have analyzed the techno-economic viability to improve three pumped hydro plants in Italy with floating PV on the lower basin. They say that, with their broad results, consequences can be extrapolated with similar regions.

Scientists from Italian Polytechnic University of Milan (Politecnico di Milano) have carried out a techno -economic optimization for the addition of Floating PV (FPV) to three existing pumped Hydro Storage (PHS) plants in the country.

‘In this work we have included various effects that have been overlooked in the literature, in particular the reduced evaporation speed of the water basin, the influence of the variation in the temperature of the solar cells due to the presence of water and the impact of the part -taxed effect of The pumps and turbines in hydroelectric factories, ”corresponding author Dr. Mat Catania told PV -Magazine. ‘By evaluating these effects, we propose a new operational strategy for pumped hydro -electric plants, which could lead to dramatic performance improvements. “

The optimization was formulated as a mixed -integer linear programming (MILP) model, where the best solution was found while both continuous and completely number of variables use under linear limitations.

“By applying this model to different plants, we want to distract broader conclusions with regard to the economic feasibility of FPV integration with PHS,” the team said. “The findings obtained from our analysis have significance beyond the specific plants studied, because they can be extrapolated to numerous hydroelectric power stations in geographical regions that share similar characteristics such as Italy.

The three analyzed PHS plants were Bargi of Northern Italy, Capriati of the Middle South, and Taloro, located on the island of Sardinia. Based on the ratio between the maximum installable FPV and the power capacity of the smallest pump, the researchers have set an integration potential parameter (IPP) metric for each factory, which reflects the assumed usability and efficiency. In this case, Taloro demonstrated the highest IPP, Capriati the lowest and Bargi is placed in between.

Image: Politecnico di Milano, Applied Energy, CC by 4.0

More specifically, Taloro has a pumping capacity of 280 MW, a upstream basin volume of 60.50 mm³, a downward basin volume of 18.80 mm³, a downward basin area of 0.82 km² and an average annual irradiation of 182.83 W/m² . Capriati has a pump capacity of 113 MW, a upstream basin volume of 8.55 mm³, a downward basin volume of 4.80 mm³, a downward basin surface of 0.11 km² and an average annual irradiation of 178.60 W/m². Bargi has a pump capacity of 330 MW, a upstream basin volume of 6.28 mm³, a downward basin volume of 43.85 mm³, a downward basin area of 1.50 km² and an average annual irradiation of 156.29 W/m².

With those parameters, among other things, as input, the MILP algorithm runs on the Pyomo software. As an output, the model then delivered the provisional business results and the optimum FPV capacity. In all cases, the FPV was only installed on the lower basin using 440 W panels with an efficiency of 20.39%.

“For each factory, four cases were taken into account for research,” the academics added. “The configurations were only PHS (case 1), PHS with FPV only connected to the pumps (case 2), PHs with FPV connected to the grid and pumps (case 3) and PHS and PV soil separated (case 4). Case 1 represents the operation of the PHS without installation of FPV and is used as a benchmark; Case 4 is intended to compare the functioning of PHS and a PV field on the ground. “

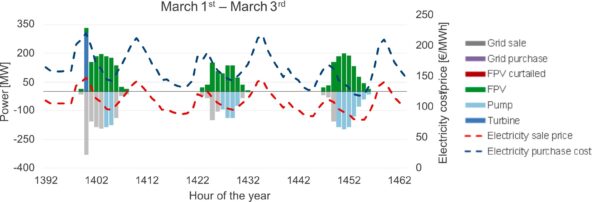

Image: Politecnico di Milano, Applied Energy, CC by 4.0

In the Bargi factory, optimization demanded a PV capacity of 305.84 MW in cases 2-4; Taloro demanded 167.19 MW in fallen 2-4; While the Capriati factory demanded a capacity of 22.43 MW in cases 3 and 4, and no PV for case 2. “Installing FPV panels prevents 8% to 18% of the water in the lower basin from evaporating, Millions of cubic meters per year and potentially increase the PHS productivity, “the team added.

Regarding performance results, the team concentrated on cases 2 and 3. Case 2 had a net cash value (NPV) of € 50 million ($ 52 million), € 15 million and € 153 million for Bargi, Capriati and Taloro respectively. The minimum basin cover was 60%, more than 100%and 10%respectively. Case 3 had an NPV of € 168 million, € 29 million and € 194 million for Bargi, Capriati and Taloro respectively. The coverage of the minimum basin was 20% for all PHS plants in case 3.

“Results of the analyzes show that the integration of FPV in a PHS system improves economic performance. The possibility of FPV installation is always operated for all Taloro and Bargi plants, while for Capriati is only used if it is possible to sell electricity back to the grid, ”the researchers noted. “In conclusion, this work shows the high potential of FPV-PHS integration that presents a promising system that can help achieve the ambitious goals set for the energy transition.”

Their analysis was presented in “Techno-economic optimization of pumped hydro-storage plants integrated with floating photovoltaic“Published in Applied energy.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content