An international team investigating wide bandgap perovskite films has announced an effective technique to control crystal orientation without compromising charge transport. The new approach was demonstrated in an all-perovskite tandem solar cell with an open-circuit voltage of 2.21 V and a certified energy conversion efficiency of 29.1%.

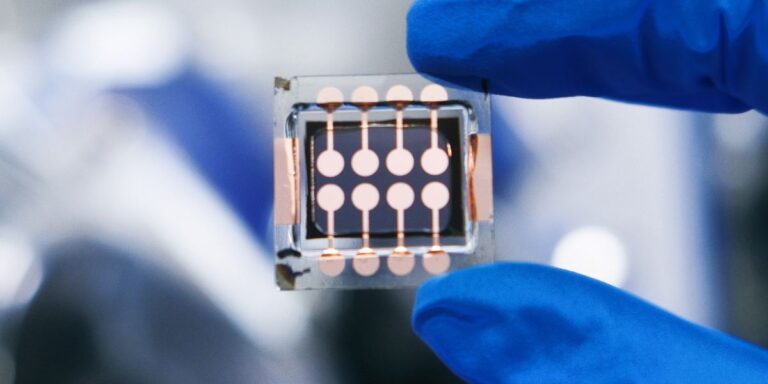

A team led by China’s Nanjing University has demonstrated a 0.049 cm2 all-perovskite tandem solar cell with reduced open-circuit voltage losses in the wide bandgap (WBG) perovskite subcell and improved overall efficiency.

This result was achieved by suppressing non-radiative recombination using a two-dimensional perovskite as an intermediate phase on the film surface. “In our laboratory tests, the device achieved a record efficiency of 29.7%, with an open-circuit voltage of 2.175 V, a current density of 16.4 mA cm-2 and a fill factor of 83.3%,” said author Renxing Lin. pv magazineadding that the result has been certified by the Japan Electrical Safety and Environment Technology Laboratory (JET).

The team said the preferred orientations in wide bandgap perovskites can be realized by increasing the amount of two-dimensional phases through surface compositional engineering, without the need for excessive two-dimensional ligands that would otherwise hinder carrier transport.

The work involved incorporating phenylethylamine iodide (PEAI) and methylammonium iodide (MAI) into the antisolvent during fabrication, forming a 2D perovskite layer on the surface of the wide bandgap perovskite subcell.

“This 2D perovskite layer served as heterogeneous nucleation sites, facilitating the vertical growth of (100) oriented 3D perovskite crystals due to the reduced interfacial energy associated with the 2D/3D heterostructures,” explains Lin. “As a result, the anti-solvent treatment not only changed the perovskite surface, but also significantly affected the crystallographic orientation of the perovskite crystals, promoting a more favorable crystal alignment.”

The approach resulted in high-quality WBG perovskite films with a (100) orientation, which suppressed non-radiative recombination in the wide bandgap perovskite subcells, achieving an open-circuit voltage of 1.373 V for a bandgap of 1.78 eV with efficiency of 21.1%. .

This was combined with a high-efficiency narrow bandgap subcell in a tandem configuration, “with a well-optimized optical-electrical matching design” to realize the high-performance all-perovskite tandem solar cell, Lin said.

Common approaches were explored for the WBG films, the researchers noted. One approach added PEAI to the precursor solution as a direct additive (DA) and the other introduced PEAI to the antisolvent as a solution process additive (SPA). Another SPA had a mixture of MAI and PEAI with a weight ratio of 1:2 as the mixed solution process additive (M-SPA) to create a local MA-rich environment.

Stability testing showed that both MA samples “proved more stable” than DA, retaining more than 85% of their original efficiency for 500 hours. However, the one without MA cations performed better. “We suggest that future efforts should focus on non-MA additives that improve 2D template formation,” the researchers said.

The work is described in detail in “All-perovskite tandem solar cells achieve >29% efficiency with improved (100) orientation in wide bandgap perovskites”, published in natural materials. The researchers came from Nanjing University, ShanghaiTech University, Renshine Solar (Suzhou) and the Swiss Ecole Polytechnique Fédérale de Lausanne.

Looking ahead, the group aims to realize the market potential for the technology in large-scale, residential and other solar PV products. Work is also underway on efficiency, long-term reliability and stability, loss reduction and efficiency improvements, including scaling up manufacturing from small to large devices.

“To make this possible, our focus will be on adapting our method for large surface coating, a scalable and cost-effective technique for mass production. This will necessitate further optimization of several parameters, including solvent composition, deposition rate, annealing conditions and coating uniformity, to ensure consistent film quality and high reproducibility on larger substrates,” said Lin. “In addition, we will tackle the challenge of maintaining uniformity in the perovskite layers on a larger scale, especially with regard to the formation of a homogeneous 2D/3D heterostructure at the film surface.”

Further work on interfaces would include “refining the materials, layer thicknesses and encapsulation methods” to improve device stability. “We are also exploring advanced characterization techniques to gain deeper insights into how the scaling process affects the crystallinity, orientation and overall morphology of the perovskite films,” says Lin.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.