The researchers conducted a case study on a solid oxide fuel cell system deployed in a nearly zero-energy single-storey, 80 m2 villa in southern Italy. They discovered that, under certain conditions of photovoltaic production, the system is able not only to meet the electrical needs of the house, but also to inject excess energy into the network.

An Italian research team has designed a 1 kW solid oxide fuel cell cogeneration (SOFC) for residential applications.

The researchers explained that compared to proton exchange membrane (PEM) fuel cell systems, SOFC systems offer higher operating temperatures, making them more suitable for all-electric buildings, such as near-zero energy buildings (NZEBs), which are residential and commercial buildings with very low primary energy demand, which can be largely met by renewable sources.

Other advantages include high combined heat and power efficiency, long-term stability, fuel flexibility, low emissions and relatively low costs.

“The great innovation of the research lies in the implementation of such an innovative system in a residential solution with complex energetic power plants, where performance is measured in the field,” the scientists explained. “The study first demonstrates the technical feasibility of such a system, highlighting the main difficulty in the installation process.”

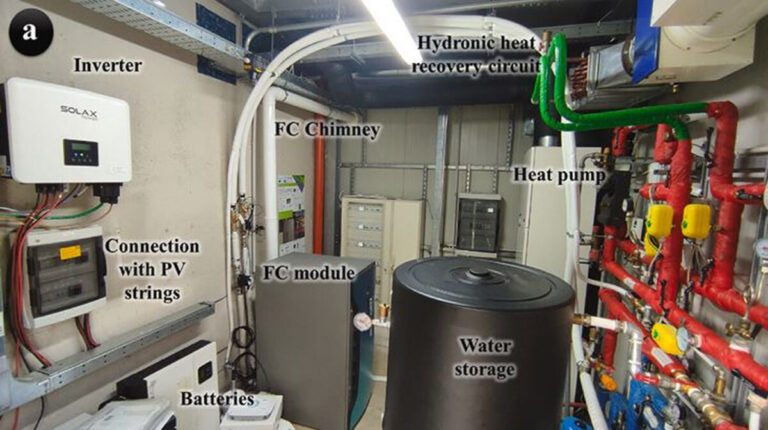

The group conducted a case study of a system deployed in a single-storey, 80 m2 NZEB villa located at the University of Sannio, in Benevento, southern Italy. It uses an air-to-air heat pump that provides heating, cooling, mechanical ventilation and domestic hot water (DHW). It also uses a 2.2m solar thermal collector2 area and horizontal geothermal boreholes, as well as a 5.3 kW rooftop PV system coupled with an 11.6 kWh lithium battery.

Image: University of Sannio, International Journal of Hydrogen Energy, CC BY 4.0

The SOFC system measures 1.2 m x 0.5 m x 0.8 m and is equipped with an inverter connected to the home electricity grid. It also uses an internal heat exchanger to recover heat resulting from the electrochemical reaction. The electrical efficiency can be up to 49% and an overall efficiency of up to 90% at a return temperature of 30 C.

“The FC runs purely on hydrogen, with a gas flow of approximately 12 l/min at 15-25 millibars, assuming nominal operation. The fuel supply first takes place via a 64 Sm storage station3 at 200 bar. Eight cylinders and three depressurization stages are placed outside,” the researchers explain. “Green hydrogen is currently being purchased. The future development of the system is to install an electrolyzer for the production of the required hydrogen on site.”

The entire cogeneration system includes closed water circuits that supply heat to a 300 liter tank, which is used to preheat the DHW generated by the heat pump. It also includes a hybrid inverter to manage the battery, PV system, FC, home electrical loads and grid connection.

Through a series of experiments, the research group was able to establish that, under certain conditions of photovoltaic production, the system is able not only to meet the electrical needs of the house, but also to inject excess energy into the network. It was also found that the system can achieve an electrical efficiency of up to 0.48 and a maximum total efficiency of 0.93.

“Considering all controlled conditions, all useful and consumed energy during the period analyzed, the electrical efficiency is equal to 0.45,” it further explained. “The overall efficiency decreases as the value of the return water temperature in the heat recovery circuit increases.”

The researchers also warned that the system may require highly qualified workers for its implementation and management, saying that another limitation is represented by the machine’s high start-up time, estimated at around 24 hours. “In addition, it is advisable to operate the FC under nominal conditions and without varying power levels regularly,” they stated.

The system was described in “Experimental characterization of hydrogen from solid oxide fuel cells in a small residential villa”, published in the International Journal of Hydrogen Energy. The research team included academics from Italian SFOC specialist SolydEra SpA, green hydrogen startup Stress Scarl, the University of Sannio and the University of Molise.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content