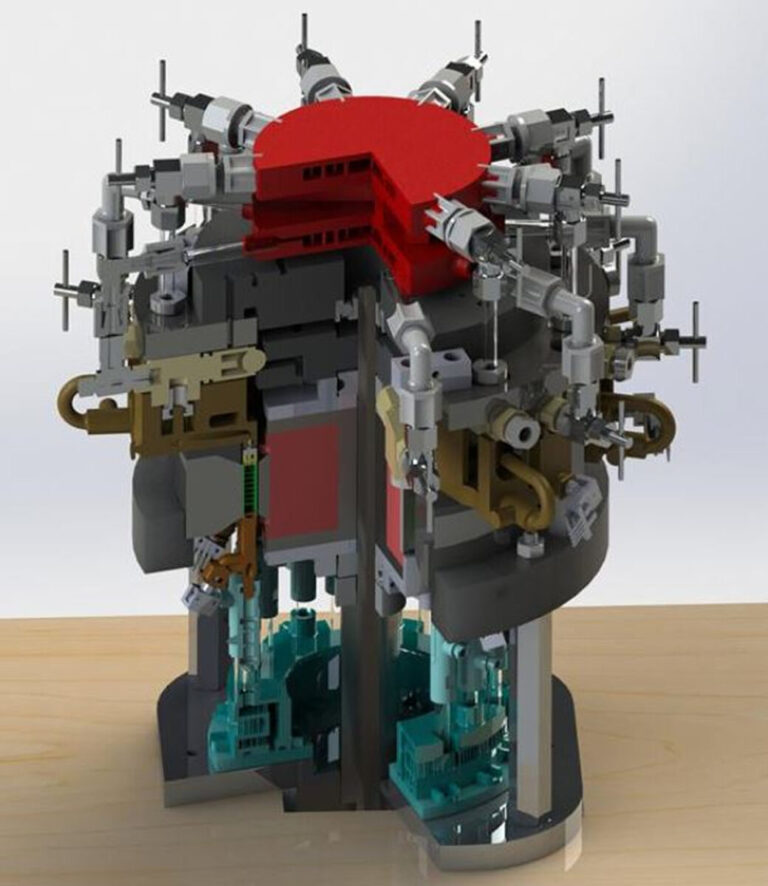

The new magnetocaloric heat pump, developed by the US Ames National Laboratory, uses gadolinium as a working medium and is said to match current vapor compression heat pumps in terms of weight, cost and performance. The system is based on an active magnetic regenerator with a packed particle bed, a magnetic source consisting of permanent magnets and high permeability magnetic steel.

Scientists at the U.S. Department of Energy’s Ames National Laboratory have built a prototype magnetocaloric heat pump (MCHP) that reportedly matches current vapor compression heat pumps in weight, cost and performance.

MCHPs use the magnetocaloric effect to perform heating and cooling. This effect consists of cooling or heating magnetic materials with the variation of an externally applied magnetic field. It is often used to develop highly energy-efficient cooling or heating systems that do not require harmful refrigerants.

In MCHPs the temperature changes due to a variation of the magnetic field, using these caloric effects to transfer thermal energy and produce heating or cooling power. All of these systems are based on an active magnetic regenerator (AMR) concept, where a heat transfer fluid is actively pumped through a bed of magnetocaloric material to transfer thermal energy to heat exchangers on the hot and cold sides.

“Magnetocaloric heat pumps are a promising replacement for cooling and heating,” said Julie Slaughter, lead author of the study. “They can eliminate refrigerant emissions and require less energy to operate.”

In the study “Scalable and compact magnetocaloric heat pump technology”, which was recently published in Applied energythe research team explained that the The system is based on an active magnetic regenerator (AMR) with a gadolinium-packed particle bed, and on a magnetic source consisting of permanent magnets and high permeability magnetic steel.

“In our basic device we kept it simple by using a single material: gadolinium. Lanthanum-iron-silicon materials have a higher power than gadolinium. So that naturally increases the power density. They are just not as readily available and require multiple materials in one device to get good performance,” Slaughter said, noting that the evaluations include estimates of a basic magnetic cooling material known as LaFeSi.

These evaluations aimed to find ways to increase the power density of the proposed heat pump system, with the scientists attempting to optimize magnetic field sources and AMR geometries while reducing space and materials. The estimates are made for cooling capacities ranging from 37 W to 43.5 kW.

“These efforts have helped ensure that the core system components match the weight of compressors available today,” said Slaughter, adding that the gadolinium material used is specifically designed to exhibit high system power density (SPD) . “The permanent magnets and magnetic steel form the majority of the mass and not the expensive magnetocaloric material, and that greatly improves affordability. We assumed that if a device weighs about the same, the costs in mass production will be about the same.”

The analysis showed that the system’s SPD increased from a baseline of 5.9 W/kg to 81.3 W/kg. “We predict that heat pump magnetocaloric SPDs will be competitive with vapor compression up to 1 kW cooling capacity,” the academics said. “In the limit case, the maximum expected power density of MCHPs with a similar design is 114 W/kg, which corresponds to compressors up to approximately 3 kW cooling capacity.”

“We have been able to demonstrate that we are competitive with the power density of some of the compressors available today,” said Slaughter.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.