Researchers in China have investigated the impact of phosphorus diffusion trap on industrial silicon heterojunction solar cells and found that higher efficiency can be achieved with optimized gas flow.

A Chinese research team led by Shanghai Jiao Tong University evaluated its impact to get in the production of heterojunction (HJT) solar cell technologies and has concluded that this can help improve device efficiency.

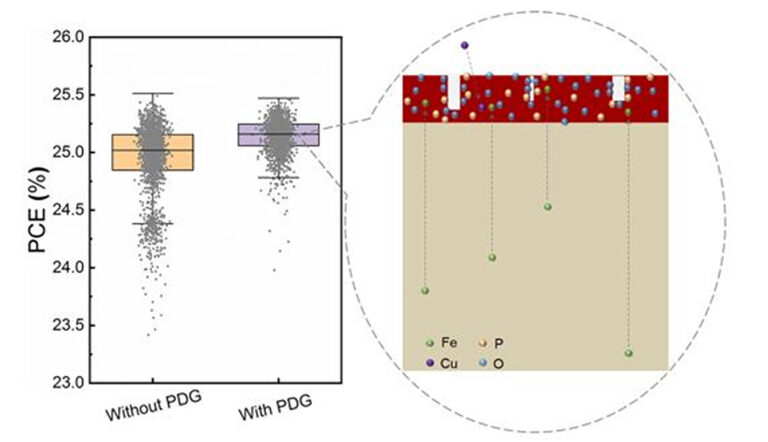

“We specifically investigated the impact of the phosphorus diffusion gettering (PDG) process on n-type HJT solar cells,” says the corresponding author of the study, Wenzhong Shen, told pv magazine. “We successfully fabricated PDG-treated HJT cells with different gas flows and discussed the influence of photoelectric properties. Optimizing gas flow to 1,000 sccm improves the balance between carrier lifetime and saturated dark current density, increasing average efficiency by 0.21%.”

Gettering is widely used in the PV manufacturing industry. It involves three steps and is used during crystal growth to remove inclusions and other forms of defects in wafers. This process first releases the impurities into a solid solution and then undergoes diffusion through the silicon. Finally, they are confined in an area away from the active circuit areas of the wafer.

Getering is already embedded in most current solar cells, via phosphor diffusion in PERC or PERx devices, as well as in Al-BSF cells. It is also embedded in TOPCon solar cells, although its effectiveness varies widely, and in silicon heterojunction cells It can be used as a pretreatment to improve the quality of silicon substrates.

Phosphorus diffusion is the most widely used and researched method to date gettering technology in the solar energy industry. However, it is the underlying one mechanisms are still controversial and unresolved. Boron diffusion is described as highly effective only under unconventional process conditions and is recommended for doped poly-Si/SiOx structures, providing a route to simultaneously achieve p+ doping and a strong getter effect.

In the study “Revealing the Effect of Phosphorus Diffusion Capture on Industrial Silicon Heterojunction Solar Cells”, published in Solar energy materials and solar cellsShen and his colleagues explained that they validate the effects of PDG on 182mm x 91mm HJT devices with an average efficiency of more than 25%. “It is known that the effect of PDG decreases as the efficiency of solar cells increases,” he pointed out.

The team found that phosphorus diffusion takes the form of circular channels rather than the entire plane, and that the effect of gettering is concentrated in the half-edge region of the substrate rather than the center and edge. “To our knowledge, these results have not been reported before,” Shen added.

The PDG process was also found to have an effect on cell square resistance, effective minority lifetime, and saturated dark current density. In addition, free energy loss simulations have been performed to quantify the power loss at different gas flows.

Thanks to the optimized gas flow, the efficiency of the solar cells reached 25.14%, compared to 24.93% for a reference cell manufactured without the PDG treatment. The main efficiency gains are partly due to improved open-circuit voltage and short-circuit current and mainly to an improvement in the fill factor.

“Overall, we believe that the current work demonstrates the feasibility of low-cost and high-efficiency industrial HJT solar cells based on the PDG process,” Shen concluded. “Our research proves that the further optimized gettering process is highly effective for the production of low-cost silicon solar cells, reducing dependence on high-purity wafers.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.