The nanocellulose film can be used for light management because the light scattering is adjustable. It also exhibits a transmission of more than 80% at 550 nm.

An international group of researchers has developed an environmentally friendly multifunctional nanocellulose (NC) hybrid film for both PV and packaging applications.

In the context of PV, the ability to adjust the light scatter or haze of the film can be useful for lighting management and as a protection system against lighting effects. Nanocellulose is a cellulosic material that has been processed at the nanoscale and usually comes from plants, algae or bacteria.

“This study was developed in the application contexts of packaging and solar cells, where key properties are crucial for the performance of these materials,” the team explains. “For example, an ideal packaging film material must have sufficient mechanical and barrier properties. Optical transparency may not be required, while features such as water resistance may be essential. On the other hand, for solar cell substrates, the critical requirement is high transparency, followed by adequate mechanical properties, low roughness and water resistance.”

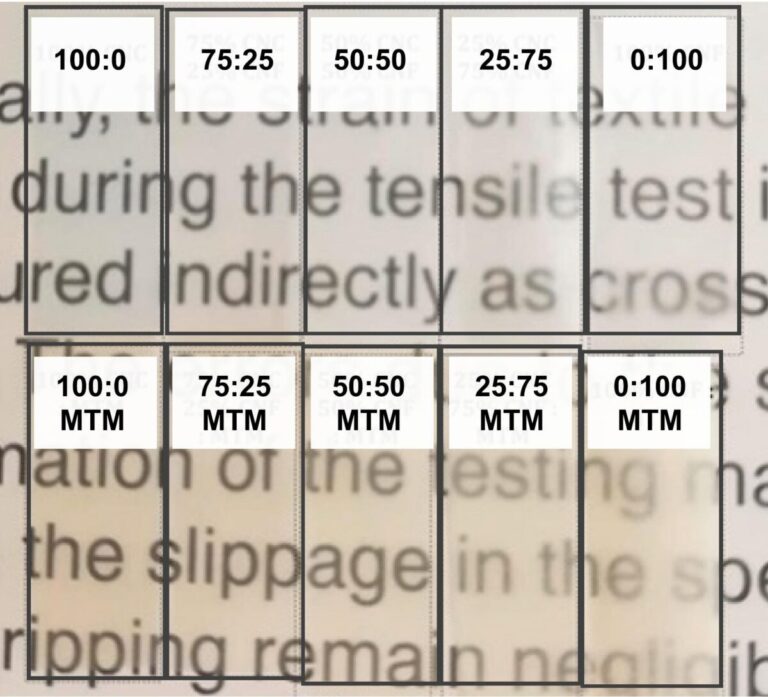

Different combinations of cellulose nanocrystals (CNC) and cellulose nanofibrils (CNF) were tested in the preparation of the films, namely at mass ratios of 100:0, 75:25, 50:50, 25:75 and 0:100. Additionally, all of these mixtures were also tested with a nanoclay known as montmorillonite (MTM). The films containing MTM consisted of 50:50 cellulose (CNC:CNF): MTM by mass.

“Films (25 g⋅m-2) consisting of CNC and/or CNF, with and without MTM, were fabricated by solvent casting. The suspensions were stirred overnight, poured into polystyrene petri dishes and dried at 23°C in a 50% relative humidity environment, the group explained. “After air drying at 23 C and 50% RH, all films were dried for a further hour at 150 C. One film from each system was placed in a frame to dry under tension, initially at 23 C and 50% RH. followed by an hour at 150 C. The tension-dried film was used for subsequent mechanical analysis, where it is important that the films are not wrinkled.”

Image: University of Turku, International Journal of Biological Macromolecules, CC BY 4.0

After producing the films, the academics tested them on a number of possibilities, depending on whether they were packaging or PV applications. Namely, they were tested for physical characteristics, tensile properties, water interaction, optical properties, color stability under artificial sunlight and surface morphology.

Compared with the combinations containing MTM, CNC:CNF films without MTM showed better potential for optoelectronic applications due to the higher transmittance of more than 80% at 550 nm. They also had good smoothness, with root mean square (RMS) roughness of 17 nm, 89 nm and 91 nm for CNC:CNF ratios of 100:0, 25:75 and 50:50, respectively.

“The hybrid films showed transmittance greater than 60% and haze ranging from 5% to 60% at 550nm, which could be beneficial for light management,” the academics also added, referring to their potential PV applications. “Films with MTM provided UV protection up to 250 nm and swelling resistance of 28-53%, which could also benefit optoelectronics by extending their lifespan.”

Their findings were presented in “Multifunctional hybrid nanocellulose films: from packaging to solar photovoltaics”, published in the International Journal of Biological Macromolecules. Scientists from Finland’s University of Turku, Sweden’s RISE Research Institutes of Sweden and KTH Royal Institute of Technology, China’s Zhejiang University, Switzerland’s Swiss Federal Technology Institute of Lausanne (EPFL) and the Netherlands’ Wageningen University and Research conducted the research .

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content