A Chinese research group has developed a new radiant cooling technology for photovoltaic devices. It consists of a chamber made of ethylene-tetrafluoroethylene and polydimethylsiloxane that, when placed above the solar cells, can reportedly achieve an average cooling capacity of around 40 W/m2.

Researchers from China have developed a new radiant cooling technology for photovoltaic devices that can reportedly achieve a cooling power density of up to 40 W/m.2 and a photovoltaic power density of up to 103.33 W/m2.

Radiative cooling occurs when an object’s surface absorbs less radiation from the atmosphere and emits more. This causes the surface to lose heat and a cooling effect can be achieved without the need for electricity.

The scientists explained that their transmission-type daytime radiation cooling system consists of a chamber made of ethylene tetrafluoroethylene (ETFE) and polydimethylsiloxane (PDMS) placed above the solar cell. These materials have both high solar transmittance and mid-infrared emissivity.

“Solar cells exhibit significant absorption capacity in the mid-infrared in addition to the sunlight band,” the team explains. “Traditional daytime radiative cooling materials exhibit high reflectivity within the sunlight band (0.28–2.5 mm) and high mid-infrared emissivity in the atmospheric window of 8–13 mm. The compatibility of daytime radiant cooling with solar cells for efficient energy conversion has presented challenges due to the need to reflect sunlight.”

To overcome these challenges, the team started analyzing functional groups, which resulted in finding ETFE and PDMS as the best options. Then, different thicknesses of ETFE films and PDMS films were tested. Ultimately, the team decided to use ETFE with a thickness of 150 mm as the top layer material for the chamber and PDMS with a thickness of 5 mm as the bottom layer material for the chamber.

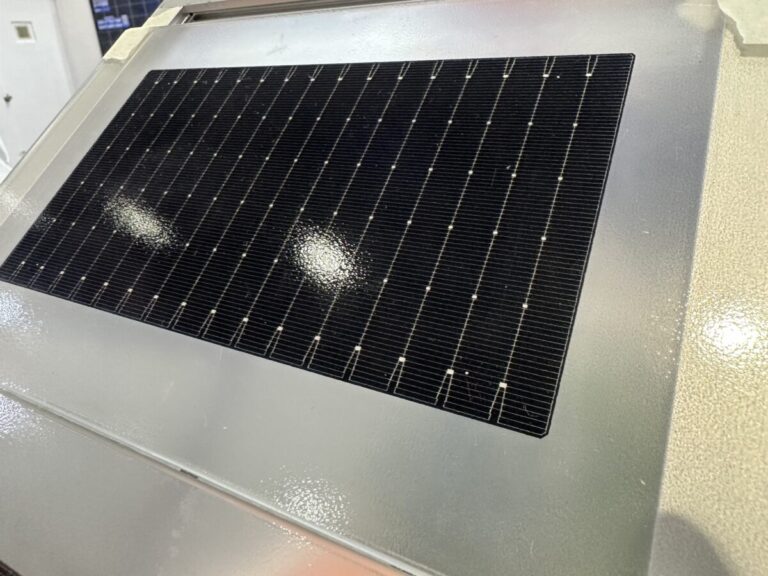

“A laser engraving machine was used to cut two acrylic panels, each measuring 20cm in length and 12cm in width, into a blank rectangle with dimensions of 17cm in length and 10cm wide in the centre,” the academics said. “The ETFE and PDMS films were sandwiched between the acrylic panels and secured with screws, creating a 5mm thick chamber between the two films.”

The chamber was placed over a monocrystalline silicon solar cell with an efficiency of 13%. To optimize the efficiency of radiant cooling, an air pump introduces air through the entrance to the chamber and exhausts it from the other side at a flow rate of 20 l/min. This experimental system was tested outdoors on a sunny October day in Nanjing, eastern China.

“The device shows excellent stability over six hours and exhibits an average cooling capacity of approximately 40 W/m2,” the scientists said. “The maximum photovoltaic power can reach 120 W/m2 in the afternoon without the room; however, this value decreases slightly to 103.33 W/m2 when covered with the room. Moreover, the energy conversion efficiency of the solar cell is 11.42%, compared to 12.92% for the bare solar cell.”

After the field experiment, the team ran a multiphysics simulation using the COMSOL software to see if the system could be improved. “Simulation results indicate that improving the airflow rate in the air chamber and reducing the absorptivity in the sunlight band can significantly improve performance. When the absorption capacity of the cooler drops to 1%, the radiant cooling capacity can reach 68.74 W/m2,” they further explained.

The system was presented in “Tandem radiation cooling during the day and solar energy generation”, published in Cell reports natural sciences. The team included scientists from China’s Nanjing Aerospace University and the Chinese Academy of Sciences.

Radiant cooling was recently applied to the cooling of solar panels by researchers from Shanghai Jiao Tong University in China, Purdue University in the United States, the Catalan Institute of Nanoscience and Nanotechnology and the Instituto de Ciencia de Materiales in Spain, and the Jordan University of Science and Nanotechnology. Technology and the Australian College of Kuwait.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.