China’s Fujian Metrology Institute (FMI) and the National Photovoltaic Industry Measurement and Testing Center (NPVM) have developed a metrological traceability system for both silicon and perovskite solar cells. The calibration system consists of a monochromatic light system, a bias light system, a 3D motion measurement platform with temperature control and an electrical measurement system.

China’s Fujian Metrology Institute (FMI) and the National Photovoltaic Industry Measurement and Testing Center (NPVM) have developed a metrological traceability system for solar cell technologies based on silicon or perovskite materials.

The researchers explained that there are currently three methods for the calibration and traceability of solar cells: the Physikalisch-Technische Bundesanstalt in Germany (PTB); the National Institute of Metrology of China (NIM); and the Industrial Technology Research Institute in Taiwan (ITRI).

The three methods are all based on differential spectral responsivity (DSR), a standard method to measure the spectral responsiveness of photovoltaic detectors at high irradiation levels. “The PTB DSR calibration system currently has an uncertainty of 0.56% when measuring the short circuit current of the reference solar cells, and those of the NIM and ITRI have uncertainties of 0.9% and 0.7% respectively,” they specified.

The Chinese team set up the new system by referring to the IEC 60904-4 standard, which sets the requirements for calibration procedures for the traceability of silicon solar cells, and the IEC 60904-2 standard, which sets the requirements for the classification, selection , packaging, marking, calibration and maintenance of photovoltaic reference equipment.

“We first developed a calibration system with differential spectral responsivity (DSR) and its measurement method, and then used this system to realize the calibration transfer from the standard detector to the solar cell on the World Photovoltaic Scale (WPVS) that served as the primary reference. measuring capacity for primary reference solar cells,” they further explained.

The proposed DSR method can measure the absolute spectral responsiveness of a WPVS solar cell under a white bias light of 1000 W/m2 in the range of its effective response wavelength. It can then compare these values with those of the reference solar spectral distribution AM1.5 according to the IEC 60904-3 standard, which describes basic measurement principles for determining the electrical output of PV devices, and calculate the calibration value of the WPVS solar panels . cell.

The whole procedure is implemented by maintaining the temperature of the reference solar cell and the standard detectors at 25 C, using a white bias light adjustable in the irradiance range of 0.01-1.2 solar, and using a uniform monochromatic light that is adjustable between 280 nm and 1200 nm.

The group also created equipment suitable for both silicon and perovskite cells and said this equipment makes it possible to use solar simulators to evaluate cell performance by transferring data from WPVS PV devices to the secondary reference solar cells.

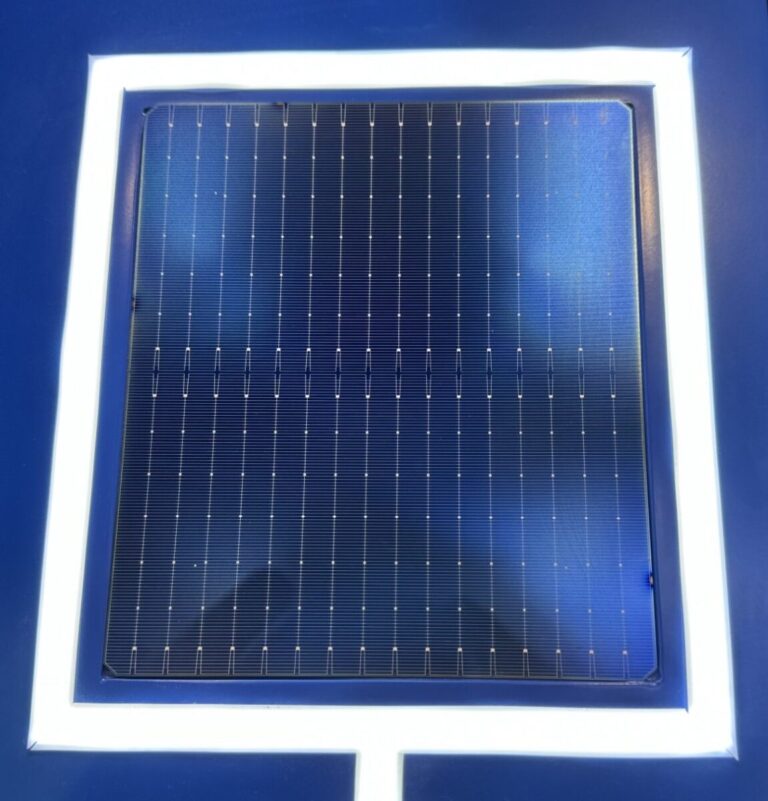

The calibration system consists of a monochromatic light system, a bias light system, a 3D motion measurement platform with temperature control and an electrical measurement system.

The monochromatic light system is equipped with a xenon lamp, a halogen lamp, two 3-grid monochromators, a chopper, a filter wheel and an optical lens module, while the bias light system uses a halogen lamp array and programmable DC power supply. Furthermore, the measuring platform consists of a 3D high-precision automatic displacement platform, a temperature-controlled platform and a programmable, high-precision temperature-controlled system. Finally, the electrical measurement system is based on two signal preamplifiers, two lock-in amplifiers, a high-precision digital multimeter with a multi-channel data acquisition device and data acquisition software.

“The developed calibration system has twice participated in international comparisons, demonstrating an uncertainty of 0.7% and achieving ‘international equivalence’, reaching world-class levels, the scientists confirmed.

The new system was introduced in the study “Setting up a metrological traceability system for solar cells”, published in Dimensions: sensors.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.