The proposed cell is based on indium gallium phosphide (InGaP), indium gallium arsenide (InGaAs) and germanium (Ge) and has an active surface area of 0.25 mm2. It can be used for photovoltaic microconcentrator (CPV) applications.

A Canadian research team recently developed a micrometer-scale III-V solar cell for applications in concentrated solar photovoltaics (CPV).

Gallium arsenide (GaAs) and other III-V materials – named after the groups in the periodic table to which they belong – are among the best known in terms of efficiency potential for solar cells. However, their high production costs have so far limited them to niche applications powering satellites and drones. For these devices, low weight and high efficiency are more pressing issues than the cost of the energy produced.

“The biggest disadvantage of these materials is their cost, which is typically more than two orders of magnitude more expensive than widely deployed technology,” the scientists said. “To address this problem, concentrated photovoltaic (CPV) technology promises to reduce costs by adding concentration optics to solar cells, limiting the use of III-V materials.”

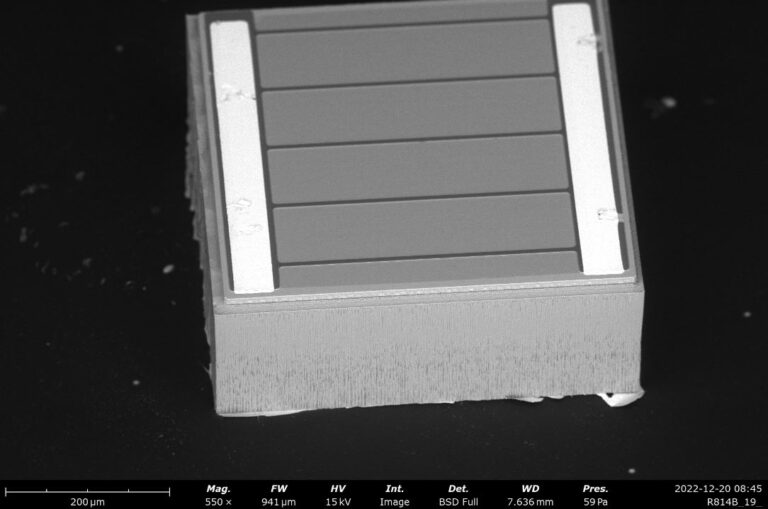

The proposed solar cell is based on indium gallium phosphide (InGaP), indium gallium arsenide (InGaAs) and germanium (Ge) and has an active surface area of 0.25 mm2.

“Our solar cell achieved the highest no-load voltage for InGaP/InGaAs/Ge of different sizes in the literature, as far as we know,” said the study’s lead author, Corentin Jouanneau. pv magazine. “The device also achieved an energy conversion efficiency of more than 30%.”

In the newspaper “Fabrication and characterization of high-performance sub-millimetric InGaP/InGaAs/Ge solar cells”, published in Solar energy materials and solar cells, Joanneau and his team explained that they built the cell with a metal contact made of nickel (Ni) and gold (Au), and with an anti-reflection layer based on silicon nitride (SiN) and silicon oxide (SiO).

The use of a plasma process enabled wafer losses of less than 10% and the design of complex shapes, the team noted. They used a process based on plasma etching for cell isolation and singulation, which reportedly allows the fabrication of solar cells of any size and shape. As a result, they were able to produce cells ranging in size from 12.25 mm up to 0.01mm and different shapes: round, triangular, maple leaf, hexagonal.

The cells were then tested under standard lighting conditions and a light intensity of 0.25 mm2 cell proved to be the champion device with an efficiency of 30.61% and a record-breaking open-circuit voltage of 2.39 V. This result was attributed to “excellent” sidewall passivation.

The smallest device, which measures only 0.01 mm2, achieved an efficiency of 21.40%.

“These cells were not manufactured for their performance, but to demonstrate the capabilities of plasma etching,” the academics explained, noting that their work was primarily aimed at identifying the cells most affected by perimeter recombinations.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.