A research team in the Netherlands has investigated how copper planar air core inductors can deliver the required inductor properties to support the power conversion of sub-modules into PV modules. The scientists claim that implementing MPPT at the sub-module level can increase the panel’s tolerance for shading.

Researchers from the Dutch Delft University of Technology have attempted to embed power electronics in photovoltaic modules with the aim of increasing the shade tolerance of panels via Maximum Power Point Tracking (MPPT).

Their work consisted of conducting a feasibility study on whether copper planar air core inductors can deliver the required inductor properties to support power conversion of sub-modules into PV modules. They claim that implementing MPPT at the sub-module level can ensure that shading on a few cells or parts of the module has minimal impact on overall performance.

“A common approach to improving the inductance of an inductor involves using a ferromagnetic core made of material with high magnetic permeability. However, this study examines planar inductors without such a core,” the researchers explain. “Since the common materials for PV modules all have a relative magnetic permeability close to unity – comparable to the magnetic permeability of vacuum and air – this design is called air core inductors.”

In particular, they investigated how the planar air core inductor design can be modified to achieve the desired inductor performance and evaluated the feasibility of integrating these inductors into a sub-module level power converter.

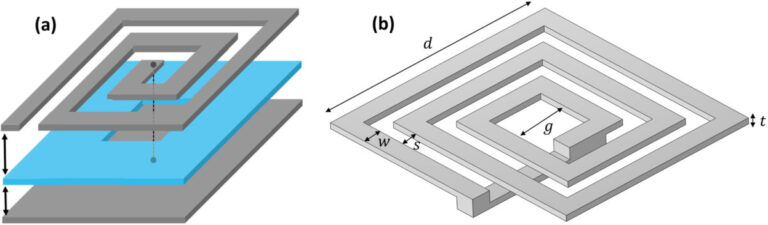

The simulated configurations use copper as the conductor material for the inductor, with an area of 12.5 cm x 12.5 cm, which is the maximum available area for a 12.7 cm x 12.7 cm solar cell. The inner terminal of the inductor is connected to the metal back of a PV cell, while the outer terminal can be connected to an external circuit. The inductor is separated from the PV cell by an electrically insulating layer.

The performance of the inductors was simulated using the finite element method simulator COMSOL with different coil design parameters. They were tested with a different internal diameter or center gap, track spacing, track width and thickness. With those size variations, the AC inductance and AC resistance of the inductors were measured.

“It has been shown that a minimum track spacing of several millimeters is necessary to limit the proximity effect at frequencies of 50 kHz and above,” the group said. “Additionally, it was observed that increasing the center gap size or the number of turns can increase the inductance, although both approaches have the disadvantage of increased inductor resistance. The simulated coil geometries yield induction values between 0.3 𝜇H and 3.2 𝜇H.”

After these simulations, the feasibility of implementing these inductors in an exemplary DC-DC boost converter was evaluated.

The group found that to reduce current ripple from a solar cell array with such inductance values, a significant switching frequency of at least several hundred kHz is required. “Additionally, at 500 kHz, an inductor thickness of approximately 0.5 mm is required to keep the ohmic losses in the inductor below 2% of the total power generated under standard test conditions,” the report said.

The system reportedly demonstrated feasible combinations, although there were significant challenges to sub-module integration. “Although the focus of this research is not on production, it should be noted that the required range of inductor thickness exceeds the capabilities of screen printing, the main technique used by the PV industry for metallization of solar cells,” the team emphasizes .

Their findings were presented in “Feasibility study on planar air core inductors integrated into photovoltaic modules to facilitate embedded power electronics”, published in Energy reports.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.