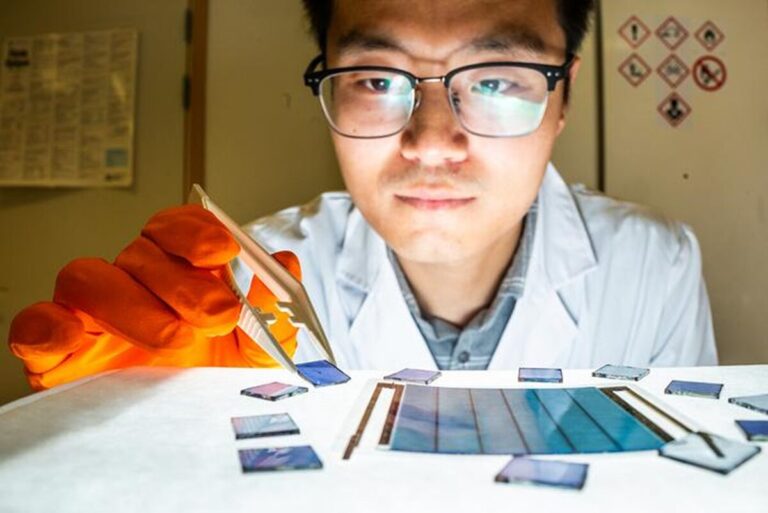

An international research team has manufactured organic solar cells using non-toxic solvents. The researchers identified interactions between the side chains of the acceptor material and the solvent, along with interactions between donor and acceptor materials, as key factors for controlling morphology in organic solar cells.

Scientists led by Sweden’s Linköping University have developed organic solar cells using various environmentally friendly solvents to identify key factors that influence the cells’ morphology.

The scientists said that optimization of morphology has been crucial in achieving energy conversion efficiency (PCE) of more than 20% in organic solar cells. Their article – “Equally high efficiency of organic solar cells processed from different solvents reveals key factors for morphology control”, recently published in Nature energy – underlines the well-established role of solvent processing in optimizing morphology to improve PCE.

Rui Zhang, the lead author of the study, said it is important to understand the entire solar cell manufacturing process to choose the right solvent.

“This includes knowing the initial structures of the solution, observing the dynamic processes during evaporation and controlling the final structure of the solar cell film,” said Zhang.

The team mapped the molecular interactions between the electron-transporting materials and the solvent using a series of advanced synchrotron X-ray and neutron techniques. This allowed them to develop a design principle for organic solar cells that turned out to work for many different harmless solvents.

The design principle was tested by developing a new acceptor material, BTP-TO2, which incorporates an oligo side chain (ethylene glycol) attached to the central nitrogen atom of the benzotriazole moiety. The scientists said that BTP-TO2 leads to a similar active layer morphology when processed from a wide range of solvents, both halogenated and non-halogenated. This process was found to produce solar cells that consistently exhibited PCEs of approximately 19%.

The researchers then investigated the intrinsic molecular conformations and interactions in the solution and film states at the nanoscale level, to identify the morphological design rules for non-fullerene-based organic solar cell blends.

The study outlines key design principles to improve the performance of organic solar cells. It emphasizes improving the interaction between the side chains of non-fullerene acceptors and the solvent to maintain stable molecular conformations in different solutions.

It also calls for a reduction in intermolecular interactions between polymer donors and non-fullerene acceptors to promote a rod-like conformation of the polymer donor. This configuration favors its preferential precipitation, ensuring consistent film morphology of the mixture regardless of film formation dynamics. These strategies are aimed at optimizing the structure and efficiency of the solar cell material

The researchers said their understanding of morphology control could support practical applications requiring green solvents for large-scale processing. They suggested that water could serve as a solvent in the future.

Scientists from China’s Soochow University, the Chinese University of Hong Kong, the University of Arizona, the University of Illinois, Oak Ridge National Laboratory in Tennessee, Lawrence Berkeley National Laboratory in California and the Institute of Macromolecular Chemistry of the Czech Academy of Sciences Sciences all contributed to the research.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.