A new protocol to improve the sustainability of flexible solar technology

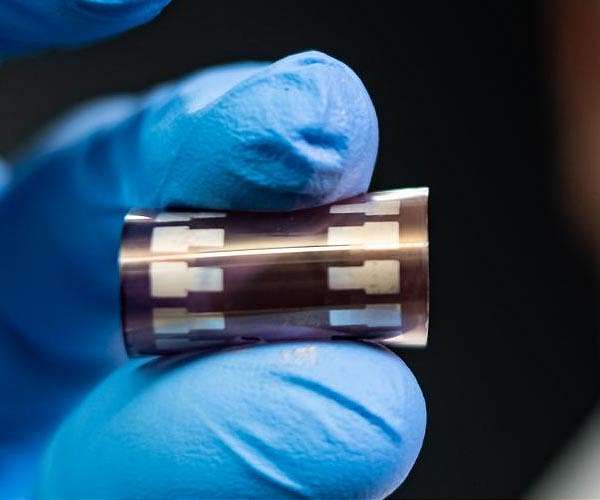

Flexible photovoltaic devices, or FlexPVs, are emerging as key solutions in applications ranging from wearable technology and smart textiles to drones and space systems. Despite significant improvements in efficiency, FlexPVs still face challenges related to the lack of standardized testing protocols for durability and flexibility, hindering their practical application.

In response, the Universitat Rovira i Virgili (URV) led an international team of 23 experts from 12 countries to develop a uniform testing protocol for flexible solar cells and panels. The initiative, published in Nature Energy, focuses on mechanical performance and provides consistent benchmarks for evaluation. “The protocol measures efficiency over 1,000 bending cycles at a strain of 1%, providing a benchmark for mechanical resistance,” explains Lluis F. Marsal, a URV researcher in electronic, electrical and automatic engineering.

This comprehensive method also assesses environmental factors such as humidity and temperature and includes encapsulation techniques to reduce degradation. The protocol ensures that these devices can perform effectively and safely under a wide range of conditions, allowing them to be used in applications that require both flexibility and durability.

The research effort was co-led by Kenjiro Fukuda of the RIKEN Center for Emerging Matter Science in Saitama, Japan, and Osbel Almora, a researcher at URV and administrator of Emerging-PV.org. Marsal, a pioneer in organic solar cell research and leader of the URV Nanoelectronics and Photonic Systems group, also played a crucial role in the project.

Expand the FlexPV potential

Flexible photovoltaic devices differ from rigid panels by using materials that allow adaptation to curved surfaces without significant loss of efficiency. Their lightweight design makes them ideal for drones, smart clothing, wearable medical devices and Internet of Things applications. The mechanical properties of FlexPVs enable resilience under extreme conditions and open doors for use in aerospace and automotive technologies.

This new testing protocol represents the first step toward bridging the gap between solar photovoltaics and flexible electronics. “The advancement of these devices will require new protocols for testing stabilization, torsion and adhesion properties, which will enable the next generation of flexible solar cells to meet future demands,” Marsal concluded.

Research report:A bend test protocol for characterizing the mechanical performance of flexible solar photovoltaics