The researchers from the German institute explained that UV-induced degradation can cause larger-than-expected efficiency and voltage losses in all dominant cell technologies, including TOPCon devices. The scientists expect that silicon nitride layers could be used to improve the UV stability of TOPCon compared to PECVD layers typically used in PERC and heterojunction cells.

Researchers from Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) have investigated the stability against UV exposure of three types of mainstream solar cell technologies: tunnel oxide passivated contact (TOPCon), passivated emitter and rear cell (PERC) and heterojunction (HJT). – and have found that they can all suffer from severe implicit voltage degradation.

They explained that UV-induced degradation (UVID) could lead to unexpected voltage and efficiency losses in the future, especially when a larger UVID track record may be available. “A prominent example of this is mild and elevated temperature-induced degradation (LeTID), which has caused unforeseen losses in PERC modules during field operation,” they stated. “Recent reports suggest that a similar scenario could repeat as a result of UVID for all three modern cell architectures.”

In solar panels, the harmful effects of UV radiation have been largely associated with UV-transparent module encapsulants and the aging of module packaging materials, leading to discoloration of the encapsulant, delamination and cracking of the backplate. In particular, UV light can contribute to the formation of acetic acid on the module’s encapsulant, damaging the cell’s contact lattice. The performance of solar cells is also negatively affected by UV radiation due to the development of surface defects. Within a silicon solar cell, UV light can cause damage to the passivation layers, to the silicon underneath and to the interface between the two.

“Currently, UV-transparent encapsulants are the standard for the module front,” said the study’s lead author, Fabian Thome, pv magazine. “The use of UV-blocking encapsulants could certainly be a strategy to reduce UVID, but at the cost of lower module efficiency. We know a number of manufacturers who are already using this strategy. It seems like a good interim solution until UVID is resolved at the cellular level.”

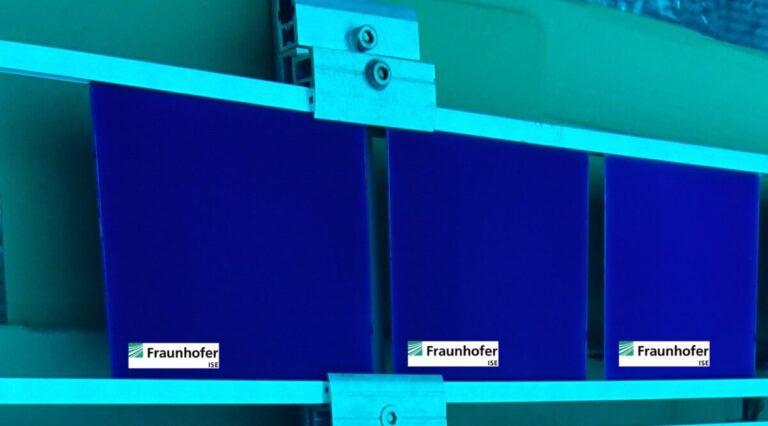

In the study “UV-induced degradation of industrial PERC, TOPCon and HJT solar cells: the next big reliability challenge?”, published in RRL solar energythe researchers explained that their analysis took into account both commercial and laboratory-scale solar cells, without disclosing the names of the manufacturers. The devices were exposed to radiation from UV-340 lamps without coverage.

“To establish a link between laboratory testing and field application, we have analyzed spectrally resolved data from a test site in the Negev Desert, Israel, since 2019,” they said. “In the UV test series, three cells per group were exposed to UV radiation from the front and two from the back, with the opposite sides covered.”

The tests showed that rear exposure resulted in less UVID than front exposure, with all technologies experiencing voltage drops of more than 5 mV after 60 kWh m−2. “After UV exposure, additional recombination – a measure of defect formation – was more pronounced for PERC than for TOPCon; but the voltage drop was similar,” Thome said. “This is because TOPCon has a higher passivation quality and therefore ‘senses’ even small amounts of defects. The higher the initial efficiency, the higher the sensitivity to even small amounts of additional defects.”

The analysis also showed that the passivation layers based on aluminum oxide (AlOx) and silicon nitride (SiNj), which are commonly deposited in TOPCon cells via atomic layer deposition (ALD), can improve the UV stability of these devices compared to layers typically used in PERC and HJT cells, which are deposited via plasma improved chemical vapor deposition (PECVD).

“Components common to all three cell technologies may also be important for UV stability. “An example would be the refractive index and thickness of silicon nitride layers, which determine the effective UV dose that reaches the silicon,” Thome concluded.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.