A research team in China improved the efficiency and stability of an inverted perovskite cell using a co-adsorbed approach to incorporate self-assembling monolayers into the hole transport layer.

Researchers in China have developed an inverted perovskite solar cell based on a hole transport layer (HTL) with a self-assembled monolayer (SAM), aimed at reducing passivation defects and increasing efficiency.

Inverted perovskite cells have a device structure known as “pin”, where hole-selective contact p is at the bottom of the intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure, but in reverse: a ‘nip’ arrangement. With nip architecture, the solar cell is illuminated via the electron transport layer (ETL) side; in the pin structure it is illuminated by the HTL surface.

The research team used SAMs made from 2-chloro-5-(trifluoromethyl)isonicotinic acid, also called PyCA-3F, while the HTL was made with [2-(9H-Carbazol-9-yl)ethyl]phosphonic acid (2PACz). A co-adsorbed (CA) approach was used for the SAM application. It consists of growing the perovskite films on 2PACz substrates with and without PyCA-3F.

The cell is built with a substrate made of indium tin oxide (ITO), the 2PACz HTL, a perovskite absorber, an electron transport layer (ETL) that relies on buckminsterfullerene (C60), a bathocuproin (BCP) buffer layer and a copper metal. contact.

Tested under standard lighting conditions, the device achieved a “certified” efficiency of 24.68%, while the control device had an efficiency of 23.3%. The scientists did not name the outside entity that certified the result.

The group hypothesized that the presence of PyCA-3F plays a crucial role in “reducing the occurrence of physical nanovoids” at the buried interface. “This remarkable increase represents a strategic advantage and contributes to the effective reduction of interfacial traps and non-radiation centers at the buried interface,” the report said.

The approach was found to effectively reduce 2PACz aggregation while improving surface smoothness and increasing the work function for the modified SAM layer, which the researchers say provides a flattened, buried interface with a favorable heterointerface for perovskite.

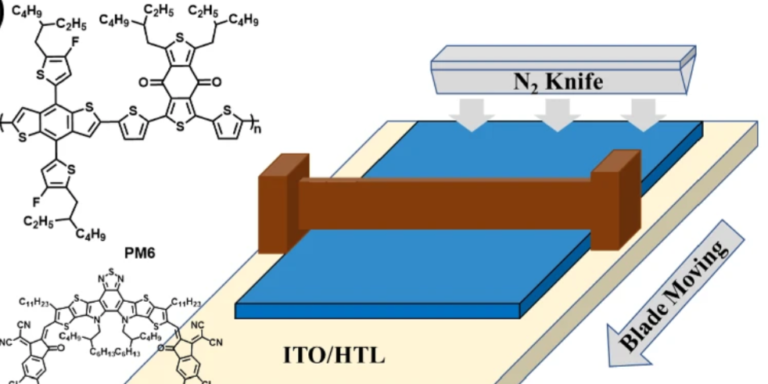

To test the proposed approach on other solar cell technologies, the scientists also fabricated 2PACz/PYCA-3F-based organic solar cells (OSCs). They used an open-air blade coating method to create the pin-structured OSC devices. The resulting devices had an efficiency ranging from 17.71% to 19.51%. The best performing OSC was based on PM1:PTQ10:m-BTP-PhC6.

The researchers noted that the OSC samples “achieved one of the best results for open-air blade coating” cast by the co-adsorbed strategy and the novel small molecule acid SAM. They also noted that the method improved the stability of both perovskite and OSC devices. “After 1000 hours of maximum power point tracking, the encapsulated PSCs and OSCs retain approximately 90% and 80% of their initial efficiency, respectively,” the team said, adding that operational stability as indicated by the maximum power point tracking results , underlined the “superiority” of the co-adsorbed approach for both PSC and OSC technologies.

“In summary, our work presents a facile, rational and effective co-adsorbed strategy to improve the performance of SAM-based devices, resulting in efficiency breakthroughs for both PSCs and OSCs based on the pin device structure, coupled with improved operational stability.” according to the research group.

The research was recently presented in the article “Co-adsorbed, self-assembled monolayer enables high-performance perovskite and organic solar cells”, published in communication about nature. The research team included scientists from China Southern University of Science and Technology, Hong Kong Polytechnic University and Chinese University of Hong Kong (CUHK).

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.