Most new solar panel manufacturers starting up in the United States are multinational companies with years of manufacturing experience. But one new American name is trying to break into the market, focusing on a unique design for the country: heterojunction technology (HJT).

Solarix will invest $63 million in an existing 423,553 ft2 facility on 56 acres of land in Forest, Virginia, supporting an initial 1.2 GW of annual solar panel production capacity. Solarix chooses HJT because company leaders have experience with the new technology, CEO Carlos Class said, and it honestly seems like a safer bet than patent-heavy TOPCon.

“There are many variants of TOPCon that have been patented by many companies. We knew that at some point there would be an infringement of the TOPCon patent [allegations]and now Trina is starting to do that,” he said. “These companies that developed their production lines here to use TOPCon in their modules are now putting a moratorium on their 2025 production plans for domestic content.”

In addition, Class said Solarix is confident in the benefits of HJT. In a warming world, HJT’s higher temperature coefficient means panels can work in more climates. And there is room to play with even more advanced technologies such as perovskites.

“HJT is a technology that, once you have developed the cell, you can continue to innovate on it. Once PERC or TOPCon is created, that’s it. That is the end of the development phase,” says Class. “We are not a company that only sources modules from Indonesia. We want to innovate.”

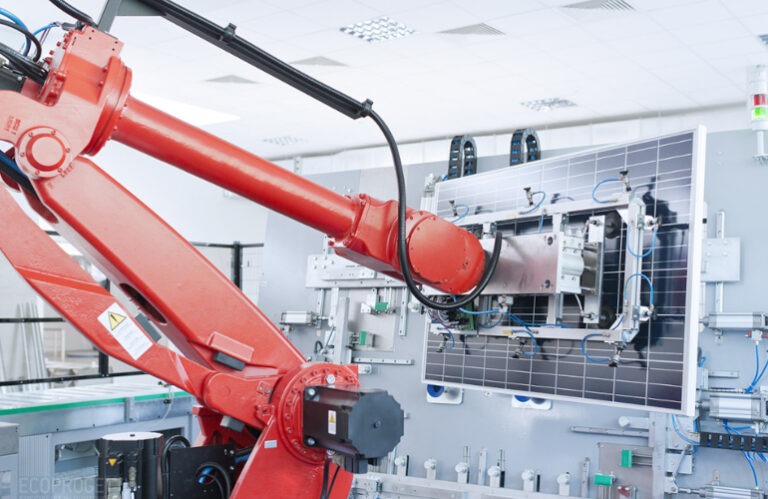

Solarix’s operations in Forest, Virginia.

Solarix CTO Napoli Gomez and COO Carlos Class Sr. know HJT very well – they worked in Europe with early HJT designs 20 years ago, Class said. The pair were also involved in production at SolarTech Universal’s short-lived manufacturing operations in Florida, where Meyer Burger technology was licensed for panels using SmartWire technology. HJT experience in the United States is rare, as only Meyer Burger’s Arizona operations use the technology. That’s why Solarix focuses on the niche design.

“It is very expensive to make and market HJT when there is no demand for it,” Class said. “To produce TOPCon, you take a mono-PERC line and add a few more components to it and you create TOPCon. To make HJT you need to take the mono PERC line, wipe it away and throw it away. You have to introduce a whole new line, because there are new processes. Many companies are not eager to make that initial investment.”

Class said that as a new manufacturer without established PERC lines to rely on, Solarix can more easily start HJT operations. The goal is to begin production in the fourth quarter of 2025 and join Meyer Burger as the only domestic HJT solar panel manufacturer. 3SUN announced its intention to launch HJT cell and panel operations in Oklahoma last year, but ground has yet to be broken for the project.

Domestic purchasing

Where does Solarix source its solar cells to meet domestic content requirements? It’s a fair question, especially since Meyer Burger scrapped its domestic cell phone production plans due to market fluctuations and has losing customers as a result. Class said Solarix has established a manufacturing relationship with a U.S. manufacturer that primarily makes HJT solar cells for space applications. The undisclosed company is considering building a factory to supply Solarix with cells, but nothing has been finalized yet.

Production lines. Credit: Ecoprogetti

Solarix sources its production equipment from Ecoprogetti in Italy to ensure no components come from China.

“We do not operate on the promise that we will have no foreign ties, only American pride. We have partnerships with other manufacturers in India and other allies. They are also fighting China in their own country,” Class said. “We are a common sense team in everything we do.”

Solarix has announced 104 jobs – a realistic number for today’s modern production lines, Class said.

“Why do I have to go public and tell the state that I provide 1,275 jobs? Let’s be honest: how much do you need? Yes, maybe I produce 1,275 jobs with contractors. But in reality I have seven people on the phone per shift,” he says.

Solarix may not employ many people, but the company is invested in being a member of the community for the long term. Solarix wants to work with local universities and primary schools to interest more young people in a career in solar energy.

“We live in an area that is very community-oriented. This is not an industrial park,” Class said. “The goal with this is to create more than just a solar panel manufacturer. We want to create a community.”