The Chinese manufacturer said the device is based on dense passivating contacts that reduce the absorption of parasitic light and improve passivation. It used a lean production technique that is said to be approximately one-third more effective than TOPCon’s mainstream technology.

Chinese solar module manufacturer Longi has developed a heterojunction back contact (BC) solar cell using a laser-enhanced contact optimization process that reportedly has an overall effective processing time of about one-third compared to that of mainstream technologies such as PERC and TOPCon.

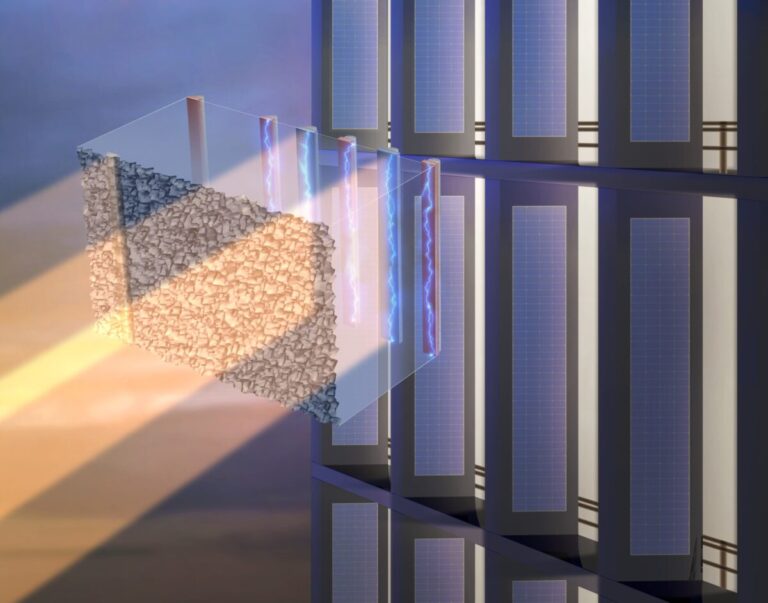

The design of the device was presented in the scientific article “Silicon heterojunction back-contact solar cells by laser patterning”, which was recently published in nature. “This cell can be used in all silicon-based PV application scenarios,” said Chaowei Xue, department director at Longi Solar. pv magazinenoting that the device is based on dense passivating contacts that contain less hydrogen compared to regular contacts used in BC cells, which he said reduces the absorption of parasitic light and improves passivation.

The company’s researchers explained that laser patterning is currently the cheapest technique for building BC cells and highlighted that so far, however, this process has produced devices with an efficiency of no more than 22.5%. Furthermore, this technique can lead to laser-induced damage in the cells and lower open-circuit voltage and fill factor because it causes degradation in the amorphous passivating contact or the crystalline silicon interface.

To address this problem, they used the three laser patterning steps known as P1, P2, and P3 to create the interdigitated n/p polarity by selectively removing N-contact, P-contact, and indium tin oxide (ITO) layers, respectively. . The P1 and P3 steps focus on isolating the back contact layers of adjacent cells and the P2 step creates an electrical path between the back contact of a cell with the front contact of an adjacent cell. The P3 step in particular is often a source of undesirable effects, such as back contact delamination, flaking or poor electrical insulation, due to residues left in the trench.

“The top-hat-shaped laser beam was used in two modes,” the research group explains. “The Overlap mode, used in P1 and P3, removed a layer completely, while the single-shot mode used in P2 preserved the area between successive shots. The single-shot mode created a partial contact instead of a full contact between the amorphous silicon hydrogenated film and the ITO layer.”

The research team built the 243.0 cm2 cell with an M6 phosphorus-doped n-type Czochralski monocrystalline silicon wafer. It deposited the dense passivating contacts via plasma enhanced chemical vapor deposition (PECVD) at 240 C. A pulsed green picosecond laser with a 250 μm spot was used to ablate the films.

The team-designed champion cell, tested under standard lighting conditions, achieved an energy conversion efficiency of 27.3%.

In addition, the academics produced a device with less indium content that achieved an efficiency of 26.5%. “We have also demonstrated an efficiency of 26.2% for HBC solar cells metallized by screen-printed copper paste (Cu) at low temperature,” they said, adding that the proposed production technique aims to reduce the use of rare indium and precious silver disconnecting the solar cells. heterojunction technology, where PERC and TOPCon have scalability limitations due to their reliance on silver contacts.

Longi did not specify whether these results have been confirmed by an independent third party.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.