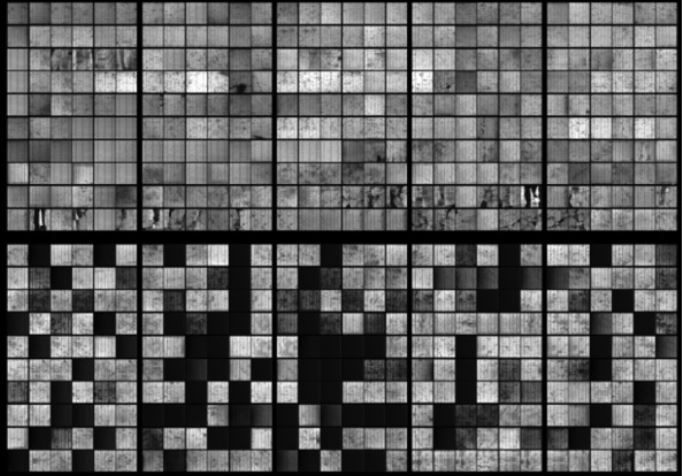

A British research team used electroluminescence imaging to inspect 167 PV installations with a total of 5 million solar cells. Defects were divided into line cracks, complex cracks, edge ribbon cracks and potential induced degradation (PID).

Researchers from the University of York carried out electroluminescence (EL) analysis on 85,000 PV modules in 167 installations across the UK over a nine-year period and found an increasing presence of complex cracks and edge cracks in recent installations .

The scientists explained that the novelty of their approach was to use EL testing exclusively under nighttime conditions, which they say improves image clarity and resolution, as well as defect detection accuracy. They also include a temporal degradation analysis from 2015 to 2023, which they say provides “unprecedented” insights into the long-term performance and degradation patterns of PV systems.

The group categorized defects into line cracks, complex cracks, edge ribbon cracks and potential induced degradation (PID). It used digital EL cameras to capture high-resolution images of the PV modules. “To facilitate the EL imaging process, the PV module was connected to a power supply, generating a preset current,” it further explained. “This arrangement is essential for inducing the electroluminescence effect in the solar panels, which reveals defects on imaging.”

The academics said this arrangement results in minimal interference from ambient light, improved image resolution and contrast, improved sensitivity to electroluminescence, consistent imaging conditions, reduced thermal stress on equipment and optimal conditions for current induction.

Image: University of York, Renewable Energy, Common License CC BY 4.0

The solar panels tested had an operational field experience ranging from 2 to 9 years, with 41,000 solar panels having a 72-cell configuration and the remainder a 60-cell design. The inspection analyzed a total of 5,592,000 solar cells. “We did not collect IV curves for all 85,000 PV modules due to the significant costs associated with such extensive data acquisition,” the academics specified.

The EL analysis showed an increasing presence of edge ribbon cracks, which occur at or near the edges of the solar cells, especially where the cell is soldered to the ribbon. These defects are usually due to stresses during module manufacturing, thermal expansion, or mechanical loading stresses.

“One of the most striking findings is the dramatic increase in edge ribbon cracks in PV systems installed after 2022,” the research team points out. “These defects, which significantly affect module performance, have increased from 7.89% in earlier installations to 28.23% in more recent installations. This trend suggests that newer manufacturing or installation techniques may introduce mechanical stresses that lead to these types of defects.”

However, the analysis also found that the degradation rate of PV systems remained below 1% per year, with most PV systems predicted to retain well over 80% of their original performance after 25 years. “This highlights the long-term sustainability of PV systems, even as they experience a gradual decline in efficiency,” she added.

Their findings are available in the article “Broad electroluminescence analysis of over 5 million photovoltaic cells for defect detection and degradation assessment”, published in Renewable energy.

Looking ahead, the researchers say they want to expand the data set, integrate advanced machine learning techniques and investigate regional variability in PV degradation rates, as well as develop improved monitoring strategies, predictive models and targeted maintenance practices.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content