Panacol, a German adhesive supplier, has launched Elecolit 3648, a one-component electrically conductive adhesive (ECA) for flexible perovskite and organic PV connections. It is designed to adhere well to a range of materials, including various types of plastic.

Germany-based adhesive technology provider Panacol has launched Elecolit 3648, a conductive adhesive for creating flexible electrical contacts on temperature-sensitive organic photovoltaic (OPV) and perovskite solar devices.

The new product is designed to bond well to plastics, such as polyimide, polycarbonate, polyvinyl chloride, acrylonitrile-butadiene-styrene and flame-retardant epoxy resin.

“The most important features for our customers are usually that the adhesive cures at low temperatures, which is important for the heat-sensitive OPV materials,” says Lena Reincke, business development manager of Panacol for OPV. pv magazineadding flexible and pliable as other desirable properties.

When it comes to dosage, Reincke noted that OPV customers preferred a one-component adhesive due to its simplicity. It is ready to use, without the need for measuring or mixing, as is the case with many conventional adhesives.

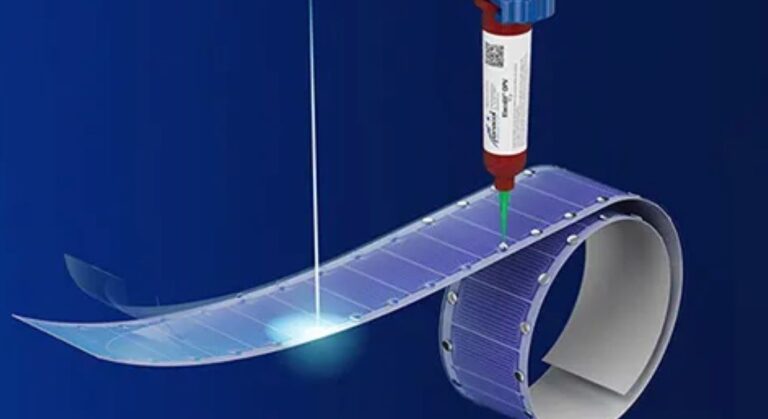

Elecolit 3648 is a solvent-free, one-component electrically conductive adhesive (ECA) with silver filler. It is a gray colored epoxy with cure times from less than 1 meter at 150 C for up to 30 minutes at 80 C with a post oven time of 24 hours to achieve full strength bonds.

Panacol, which produces a range of ECAs, said in a statement that it was necessary to develop the new, more flexible ECA formulation because even conventional ECA products that cure at low temperatures can still be brittle and inflexible. In addition, certain applications that are subject to vibration, oscillation or rapid temperature changes require an ECA with added flexibility and stretchability.

When asked about the source of demand for this type of ECA, Reincke said: “We see demand mainly in Europe and the United States, but also in Asia.”

The Elecolit 3648 ECA technology is compatible with jet printing, screen printing or conventional adhesive dispensing equipment. According to Reincke, the chosen dosage depends on the volume. For small volume production and laboratory testing, the choice is between conventional dosing, spraying or squeegee. For higher volume production, customers use jetting or screen printing methods.

Panacol Elosol, part of the German Hönle Group, produces industrial and specialty adhesives, including a range of multifunctional adhesive products for flexible solar photovoltaics and electronics.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.