Researchers in Italy have devised a dual-source heat pump system that uses both a fin coil evaporator and a solar evaporator made with three photovoltaic thermal panels. The combined operation of the two evaporators allows the heat pump to achieve a higher evaporation pressure and coefficient of performance.

Researchers from the University of Padua in Italy have designed a dual-source heat pump using CO2 as a coolant and a solar evaporator consisting of three PV-T collectors

“The main innovation lies in the combined operation of two evaporators, the fin coil and the PV-T collectors, allowing a choice between air and solar energy or their simultaneous use,” the scientists said. “The new solution presented here does not require the refrigerant flow to be distributed between the two evaporators and at the same time solves the problem of possible maldistribution at the inlet of the evaporators.”

The proposed 5 kW CO2 solar-assisted dual-source heat pump (CO2 SA-DSHP) system can work with both types of evaporators at the same time or with just one of them, where the PVT collector can act as an evaporator, as the refrigerant flows directly into the PV-T tubes.

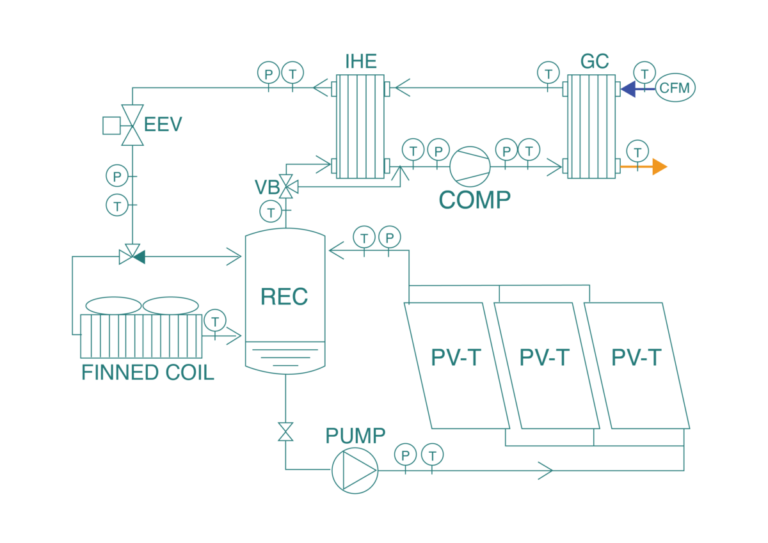

It consists of an inverter-driven hermetic vertical rotary compressor (COMP), an internal heat exchanger (IHE), a gas cooler (GC), a fin coil heat exchanger used as an air evaporator, and the solar evaporator consisting of three PV-T collectors. . The 270W PV panels were attached to a plate-and-tube heat exchanger, allowing both the evaporation of the refrigerant flow and the cooling of the photovoltaic cells, which in turn improves their performance. It also contains a throttle valve, a circulation pump and a cylindrical tank that acts as a receiver.

The system can operate in three modes: air mode (AIR-M); solar mode (SOL-M); and simultaneous mode (SIM-M). When used under the AIR-M, the heat pump only uses air as a thermal source at a low temperature, while with the SOL-M it only uses solar radiation as a thermal source. In SIM-M mode it uses both solar radiation and air.

“In all operating modes, between the low pressure receiver (REC) and the compressor suction line, the CO2 flows through the IHE, which is used to superheat the refrigerant before it enters the compressor,” the team explains. “To adjust the degree of superheat, a three-way valve (VB) is used to bypass some of the total coolant flow coming from the REC.”

Through a series of tests carried out in winter conditions, the academics assessed the system’s coefficient of performance (COP) and energy consumption. They took into account a compressor and fan speed of 50%, a pump speed of 40%, a high pressure of 80 bar and water heated from 30 C to 35 C.

“An experimental comparison between the three different heat pump operating modes was carried out under the same ambient and operational conditions,” they said, noting that the PV panels were used to achieve maximum power production.

The analysis showed that the heat pump operating in SIM-M can achieve higher pressure evaporation and higher COP compared to those in AIR-M and SOL-M. “Simulation results show that the performance in the simultaneous mode can only be surpassed by the solar mode at high irradiance and low air temperature, when the evaporation temperature becomes higher than the air temperature,” the scientists further explained.

Their findings are available in the study “The advantage of performing a direct expansion CO2 heat pump with simultaneous solar and air heat sources: experimental and numerical research”, published in Applied energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.