An international research team has investigated how thermoelectric subcooling can be integrated into propane heat pumps to reduce energy consumption in the vapor compression system. Their work showed that this combination can not only reduce electricity consumption, but also significantly improve heat pump performance.

An international research team has conducted a computational analysis on propane (R290) vapor compression heat pumps that integrate a thermoelectric subcooler (TESC) to reduce the energy consumption of vapor compression systems and found that this combination can increase the coefficient of performance of the heat pumps by 12.29% .

In the newspaper “Effect of thermoelectric subcooling on COP and energy consumption of a propane heat pump”, published in Applied thermal technologythe scientists explained that the combination of these technologies had been shown to be highly beneficial for refrigeration systems in previous research and said that propane heat pumps could also greatly benefit from thermoelectric subcooling.

TESCs are composed of thermoelectric modules (TEMs) and solid-state heat engines that use electrons as the working fluid. TEMs are widely used for the electronic cooling of devices such as personal computer processors, as well as for portable food and beverage storage systems.

The calculation model was applied to a propane heat pump for homes, intended to heat space.

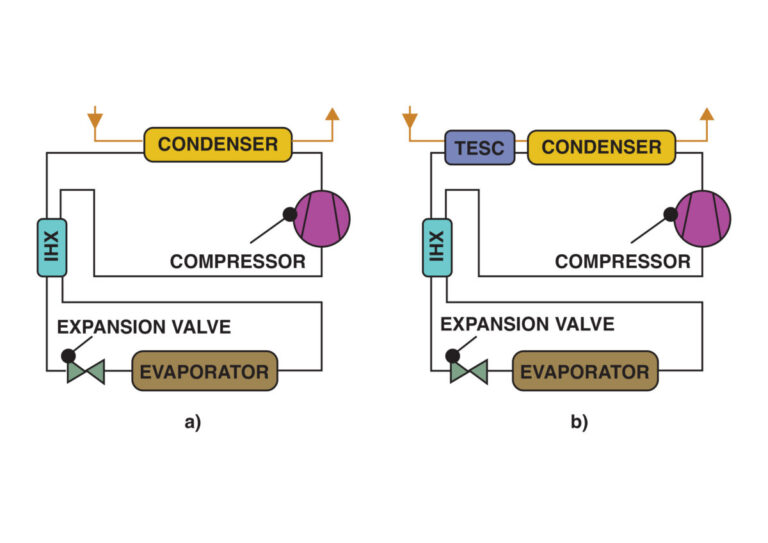

In the proposed system configuration, the TESC is located between the condenser and the internal heat exchanger (IHX). The water that needs to be heated goes through the TESC and then through the condenser. In addition, the TESC absorbs heat from the propane and thus provides subcooling at the condenser outlet, which improves the operation of the vapor compression system.

“The inlet water temperature determines the inlet to the TESC, while the outlet water temperature determines the inlet to the condenser,” the scientists explain. “Each of the blocks has different hot and cold well temperatures because the propane stream cools as it passes through the TESC system and the water stream heats up.”

The computational model is reportedly capable of developing an iterative process that assumes the exhaust temperatures of each block and solves for each block until the assumption matches the block’s operation. It also calculates the propane outlet temperature and the water stream outlet temperature, as well as the COP and power consumption of the TESC.

“The calculation model has been developed in such a way that the entire heat pump can deliver one kW of heating capacity,” the group explains. “To this end, the compressor capacity is increased at each resolution to achieve the kW heating capacity.”

In their simulations, the researchers took into account ambient temperatures between −20 C and 15 C, TEM voltage levels from 0.5 V to 10 V, a thermoelectric system consisting of 1 to 8 blocks, and two water inlet temperatures of 40 C and 55 C Mass flows, heating capacities, compression ratios, compressor capacities, cooling capacities, temperatures, COPs and energy consumption were also taken into account.

Their analysis showed that optimal TEM voltage levels are essential for maximizing heat pump performance, and that very high voltage sources are counterproductive to vapor compression. It also showed that the highest COP improvement of 12.29% was obtained at an ambient temperature of −20°C and was achieved when the TESC was designed with 8 blocks consisting of 16 TEMs.

“However, if the TESC system is reduced to half, because it consists of only four blocks (8 TEMs), the COP improvement is still 9.54%,” the group pointed out. “When the heat pump is used for space heating with fan coil units, the COP increases are 7.64 and 6.03% respectively.”

Further analysis also showed that the TESC could also improve the heat pump seasonal coefficient of performance (SCOP) by 9.98% if a TESC system with 8 blocks per kW heating capacity is integrated to heat water for conventional radiators.

The academics are currently planning to build a system prototype to confirm the results of the simulations. “The integration of thermoelectric subcooling into a propane vapor compression heat pump has been shown to be highly beneficial in terms of COP and energy consumption,” they concluded. “Moreover, thermoelectric systems have been proven to be robust, simple, flexible, reliable, cheap and easy to control.”

The research team included academics from the Public University of Navarra and Jaume I University in Spain, as well as the Silesian Technical University in Poland.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.