The new solar cell uses tungsten sulfide as a field layer on the back surface. According to the makers, this layer can be incorporated into conventional CIGS solar cells to improve their efficiency and reduce the cost of the absorber material.

Researchers from Visvesvaraya National Institute of Technology in India have proposed a new copper-indium gallium diselenide (CIGS) solar cell structure using tungsten disulfide (WS2) as the back surface field (BSF) layer.

BSF layers consist of a higher doped area at the back of the solar cell and are often used to increase the voltage of a device. WS2 – an extremely smooth, dry film lubricant coating that functions under harsh conditions – can be used in solar cells as an electron transport layer or buffer layer, and nanosheets and nanoparticles made from electronic WS2 Powders are often used in nanoelectronics, optoelectronics, gas detection equipment, hydrogen evolution reactions and energy storage devices.

“The novelty of this research work is that for the first time in the history of CIGS solar cells, an efficiency of 25.70% has been obtained through simulation work with a CIGS absorber layer thickness of 200 nm and a field layer thickness on the back surface of 50 nm,” says the researcher. corresponding author of the study, Sushama M. Giripunjetold pv magazine.

He also explained that the minimization of the thickness of CIGS cells aims to reduce the consumption of rare earth metals such as indium and gallium, as well as their cost per watt. “This impact will be clearly visible in the mass production of CIGS solar cells,” he added. “This type of structure has not been previously reported to the authors’ knowledge.”

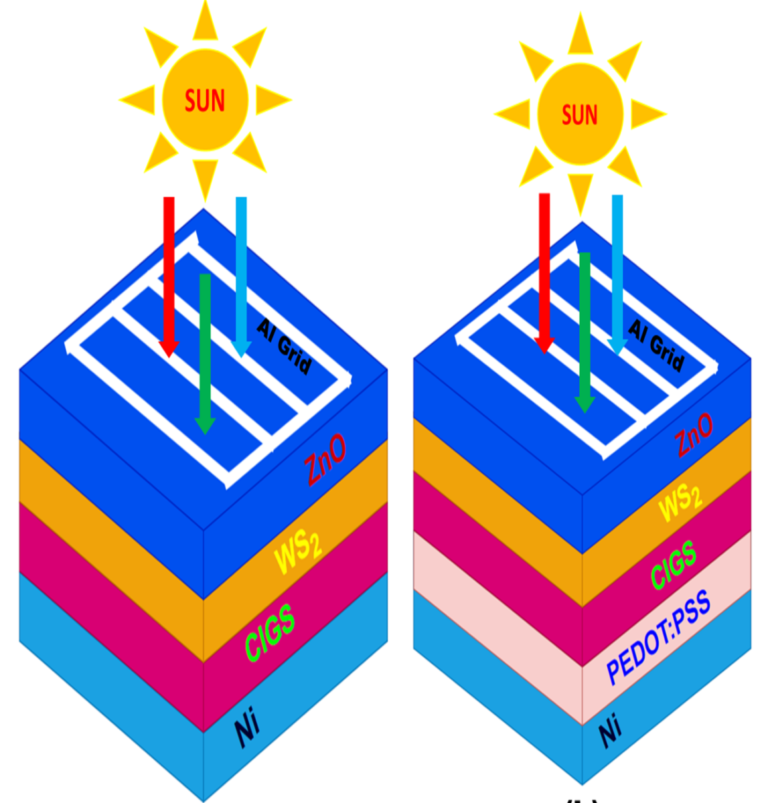

The scientists used the SCAPS-1D solar cell capacity software, developed by Ghent University, to simulate the new cell configuration. They assumed that the cell was dependent on a back contact layer made of nickel (Ni), a PEDOT:PSS layer, a CIGS absorber, a buffer layer made of WS2a window layer based on zinc oxide (ZnO), and a front electrode made of aluminum (Al).

“The BSF layer, located at the back of the cell, can reduce the recombination of charge carriers, such as electrons and holes, which in turn reduces the loss of charge carriers,” the group said. “Another factor contribution is reflection; here some of the incident light into the cell can be reflected by the BSF layer in its capacity as a reflective layer. Improving the path of light within the cell improves absorption and increases power production.”

The scientists simulated the device’s performance under standard lighting conditions and found that it had a power conversion efficiency of 25.7%, an open-circuit voltage of 0.81 V, a short-circuit current density of 39.33 mA/cm2 and a fill factor of 39.33 mA /cm2 achieved. 79.89%.

“At a defect density of 10 cm3 for the CIGS absorber layer, the device gives the best output, and based on variations in series and shunt resistance, it is confirmed that a low value of series resistance and a higher shunt resistance are beneficial for better performance,” explained them further.

The new cell concept was presented in the paper “Design and simulation of a novel high-efficiency ultra-thin CIGS solar cell device structure: plan to minimize cost per watt”, which was recently published in the Journal of Physics and Chemistry of Solids.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.