Researchers in the United Kingdom have presented a new heat pump system that can prevent heat input from being reduced during defrosting operations. The proposed concept can reportedly perform defrosting operations while ensuring continuous heating by condensing the refrigerant in the matte evaporator.

A group of researchers from the University of Glasgow and the University of Liverpool in the United Kingdom have presented an experimental flexible heat pump concept that can perform a defrost operation while avoiding a reduction in heat supply when the refrigerant condenses in the frozen evaporator.

The novelty of the proposed approach consists in defrosting the evaporator by condensing the refrigerant in it. “Our work presents a theoretical analysis under ideal conditions,” said the study’s lead author, Zhibin Yu pv magazine. “We plan to conduct experimental research to demonstrate the concept.”

“One of the most challenging issues for air-to-water heat pumps is the requirement to defrost the evaporator in low ambient temperatures and high humidity conditions,” the researchers explain in the study.A flexible multi-valve heat pump system with latent thermal energy storage for defrost mode”, which recently appeared in Energy and Buildings. “Ice build-up reduces airflow in the evaporator and increases the thermal resistance of the coils, leading to reduced heat transfer performance. This results in a decrease in heating capacity and coefficient of performance (COP) and can potentially cause a complete shutdown of the air-to-water heat pump.”

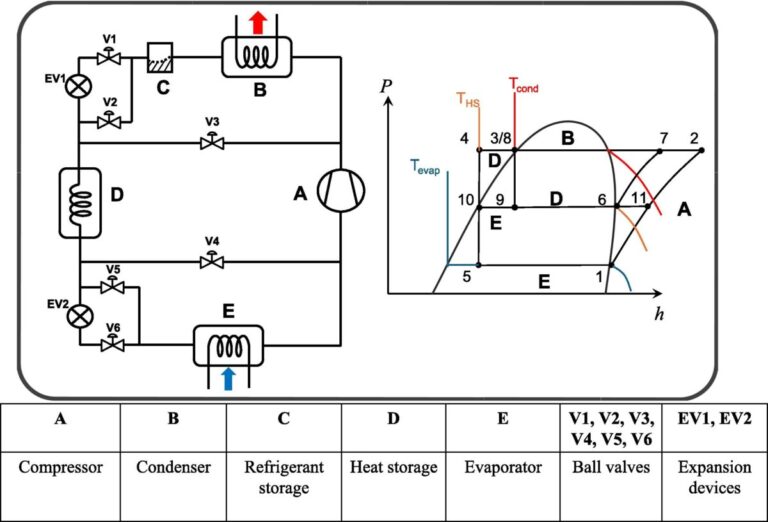

The proposed flexible heat pump system is integrated with heat storage based on the conventional Evans-Perkins vapor compression cycle, the most commonly used method for air conditioners and automobiles, and allows the system to recover and store part of the heat leaving the condenser. during defrosting, where the stored heat is reused to power the defrosting itself.

“It can perform a defrosting procedure while ensuring continuous heating by condensing the refrigerant in the frozen evaporator,” the academics further explained. “Using the heat storage as a heat source during the defrosting process increases the evaporation temperature, which leads to a decrease in electricity consumption and improved efficiency.”

The proposed system consists of a compressor, a condenser, a refrigerant storage tank, a heat storage system, an evaporator, two expansion devices and six ball valves. It operates in four operating modes: Heating and charging the heat storage; discharging the heat storage and energy saving; discharging the heat storage, energy saving and defrosting; and only charging the heat storage.

In the first mode, the systems recover subcooled heat and charge it into storage for later use, while the second mode aims to reduce energy consumption in the compressor by increasing the evaporation temperature. The third mode allows the indoor heat pump system to maintain the same heating capacity and save compressor power during defrosting, while the fourth mode enables faster heat charging by directly condensing the refrigerant inside.

The switching between these modes must be ensured by a microcontroller that opens the valves based on the required actions and with different monitoring strategies to initiate and terminate the modes at the right time.

Through thermodynamic analysis, the team analyzed the system’s potential performance and found that it can perform the defrost cycle efficiently, while extracting heat stored in the thermal storage during the charging cycle, which they say results in significant energy savings from the compressor and a higher COP.

“Depending on the storage temperature, we observed a COP improvement ranging from 7.5% to 11.2% for R410a and from 7.5% to 10.8% for R134a, compared to a conventional heat pump using a reverse cycle defrost method,” the academics pointed out. “Their low global warming potential (GWP) replacements R1234yf and R32 have also been investigated, and it has been concluded that R1234yf is the best performing refrigerant with this system, with an improvement of up to 13.2%.”

The researchers also estimated that the post-defrost recovery phase could be implemented in 1.8 minutes for R134a and R410a at their optimal storage temperature, without significantly affecting heat pump performance. They also found that R32 would take 2 minutes and R1234yf would take 1.7 minutes.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.