A Chinese-Canadian research team proposed a new PV mounting solution based on two types of spacers and two types of clamps that can be printed with common printing materials. The cost of the different solutions presented ranges from CAD1.50 ($1.10) to CAD3.83.

A group of researchers from Canada’s Western Ontario University has developed and tested 3D-printed mounting mechanisms for the wooden racks of PV modules. The open source designsIt is also claimed that, in addition to enabling distributed production, they are also cheaper and contain less energy and carbon compared to conventional racking materials.

“Wooden racks are especially suitable for ground-mounted agricultural voltaic systems, but can be used anywhere,” said corresponding author Uzair Jamil. pv magazine.

According to the research group, wooden racks also offer advantages such as ease of distributed production, lower cost per W of materials and no corrosion or rust. “The problem with wood-based shelving is that they do not allow for the standard front surface attachments that are now common with proprietary aluminum shelving systems. For the first time, this article introduces new 3D-printed clamps for front-mounting solar modules on wooden rack structures,” the researchers said.

The researchers proposed four types of mounting mechanisms, which were simulated using the Abaqus software and finite element analysis (FEA), which is often used to solve differential equations found in engineering and mathematical models. Each mechanism was simulated while being printed using one of three common printing materials: polyethylene terephthalate glycol (PETG), acrylonitrile-styrene acrylate (ASA), and polycarbonate (PC).

In all cases, the mounting mechanism was intended to support 410 W modules with dimensions of 1,880 mm x 1,042 mm x 40 mm and a mass of 19.7 kg. They are also designed to use 127mm long 6.4mm diameter lag bolts. In all 3D printed parts, a 7mm wide hole is designed to accommodate the bolt.

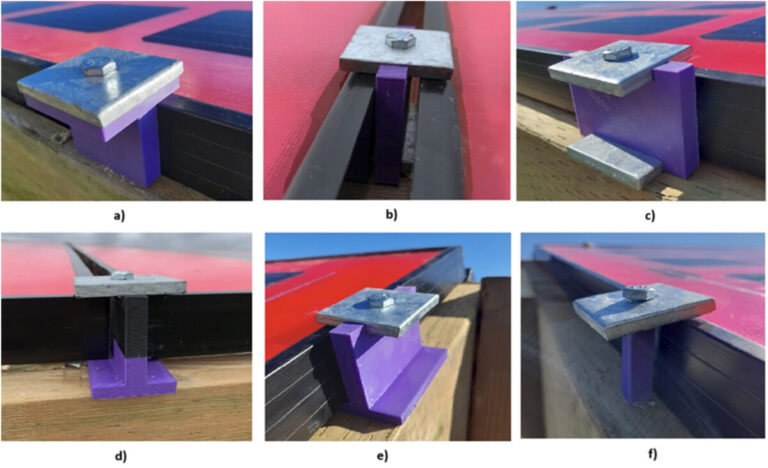

The first mechanism was a T-shaped clamp, where the T-beam rests on the frame of the PV module and holds the module to the rack structure. In this case, a flat washer is placed between the bolt and the 3D printed components to prevent damage to the clamp. Another proposal used a U-shaped clamp, which uses its own base to rest the module, while a square ring holds the module from the top.

Image: University of Western Ontario, Renewable Energy, Creative Commons License CC BY 4.0

The next two mechanisms were spacers. In the first case, a square spacer was used with a square washer to support the movement of modules. In the second, an H-shaped spacer was supported by two square rings that held the solar panels, while the holder acted as a spacer between them.

“Among all designs, the T-shaped clamp configuration showed better results with a maximum stress on the aluminum (Al) frame of 34.27 MPa,” the researchers said. “The highest stress was observed in the U-shaped spacer for spacer (4.53 MPa – PC material), bolt (32.01 MPa – PETG material) and frame (37.30 MPa) and for washer in the H spacer (42.77 MPa). However, Mises stresses for all designs are within allowable limits that qualify the clamping technique to be employed for future installations.

After the simulation results, the academics printed several mounting mechanisms to ensure their applicability in the field. “All four clamps were relatively easy to install,” they pointed out. “No installation problems were observed when tightening the lag screw. Using a pre-drill before tightening the lag screw makes tightening/screwing easier.”

In addition, the group conducted an economic analysis of production, taking into account the prices of the materials used for the printed parts, energy consumption, printing time, electricity rates, washer costs and bolt costs.

“The cost of the different solutions presented ranges from CAD1.50 ($1.10) to CAD3.83 for a square spacer and a U-shaped clamp, respectively,” they said. ”Available solutions on the market are usually all-metal clamps and sometimes even more expensive, ranging from CAD 1.76/piece to CAD 4.50/piece. This is a cost saving of 14.7% to 66% for the mounting clamps.”

The proposed mechanisms were presented in “Distributed Manufacturing for Distributed Generation: 3D Printed Mounting Mechanisms for Solar Photovoltaic Modules for Wooden Shelving,” published in Renewable energy.

“Our Free Appropriate Sustainability Technology (FAST) Research Group is currently working on fully 3D printed PV modules. We are also exploring the possibility of making 3D printed frames for frameless PVs,” said Jamil.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.