An international team of scientists has combined cyclic olefin copolymers with an aluminum oxide powder to create a filament that can be used by a 3D printer to create anti-reflective covers for PV modules. The proposed innovation can reportedly improve the efficiency of PV cells by more than 25%.

Researchers led by Saudi Arabia’s King Khalid University have developed a 3D-printed anti-reflective cover sheet for PV modules.

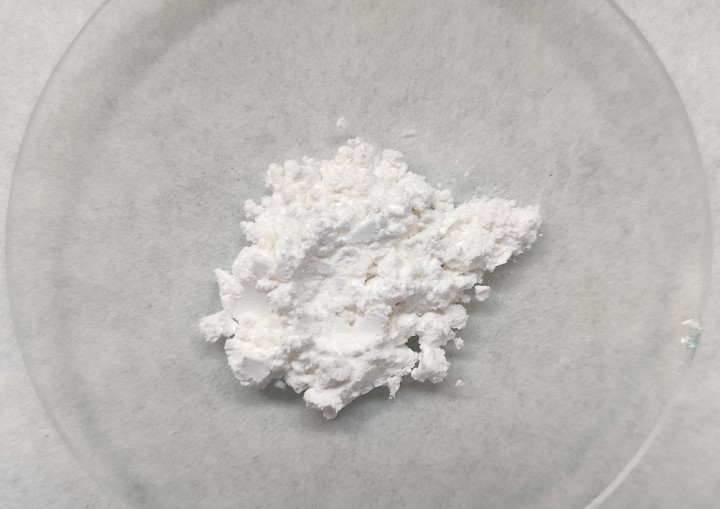

The wrapper is based on cyclic olefin copolymers (COC), to which a powder of aluminum oxide (Al2O3) has been added in different concentrations. COC are polymers with exceptional mechanical properties and transparency, while Al2O3 is known for its improved anti-reflective properties.

“The application of anti-reflective materials on the photovoltaic substrates can improve the absorption of sunlight and minimize reflection,” the researchers explain. “Currently, there is no ideal anti-reflective coating for solar cells that allows the transmission of sunlight without any reflection.”

The new cover sheet was 3D printed with a size of 52 mm x 38 mm x 1 mm and placed on polycrystalline silicon PV cells. The filament for the printer was made in-house by heating the COC polymer and Al2O3 until they melted. The mixture then passed through a spinneret and later underwent a solidification process. Five filaments were prepared, one with pure COC and the other with 1 wt% (COCA 1), 2 wt% (COCA 2), 3 wt% (COCA 3) and 4 wt% (COCA 4) Al2O3 .

“Fused Deposition Modeling (FDM) is an additive production method that works on the principle of extrusion. A 3D cover design is created using standard computer-aided design (CAD) software,” the team explains. “The samples are produced using a nozzle with a diameter of 0.4 mm. The bed temperature is kept at 60 C, the layer thickness is set to 0.2 mm, the grid angle is set to 45 and the infill pattern is linear without support.”

All products have been tested for structural and morphological behavior, mechanical characteristics, optical characteristics, external quantum efficiency (EQE) and internal quantum efficiency (IQE), spectral responsiveness, electrical characteristics and IV characteristics.

The COCA3 cover sheet was found to have the highest transmittance of 94.65% and the lowest reflectance of 5.35%. The scientists also found that reflectance increases at higher angles of incidence, from 5.35% at 0 C to 21.32% at 80 C for the COCA3 sample, and that transmittance decreases from 94.65% at 0 C to 78. 68% at 80 C for the COCA3 sample. They also found that the peak spectral responsivity increased from about 0.05 to about 0.58 A/W at 850 nm.

Furthermore, the tests showed that the hall mobility and carrier concentration gradually increased as the electrical resistance in the COCA3-covered cell decreased. The COCA3 wrapper was also found to have lower electrical resistance, as well as higher hall mobility and carrier concentration.

“The energy conversion efficiency of COCA-coated photovoltaic cells was found to increase from 13.74% to 18.34% under controlled conditions and from 12.88% to 17.21% under open-air conditions, up to a concentration of 3 wt% aluminum oxide (COCA3),” group completed. “The addition of aluminum oxide at a concentration of 4% by weight reduces both the no-load voltage and the short-circuit current, leading to a reduction in the efficiency of the photovoltaic cell.”

Their findings were presented in “Improved photovoltaic efficiency through 3D printed COC/Al₂O₃ anti-reflective cover sheets”, published in the Journal of Materials Research and Technology. Scientists from King Khalid University in Saudi Arabia, India’s Kongu Engineering College and Velalar College of Engineering and Technology conducted the research.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.